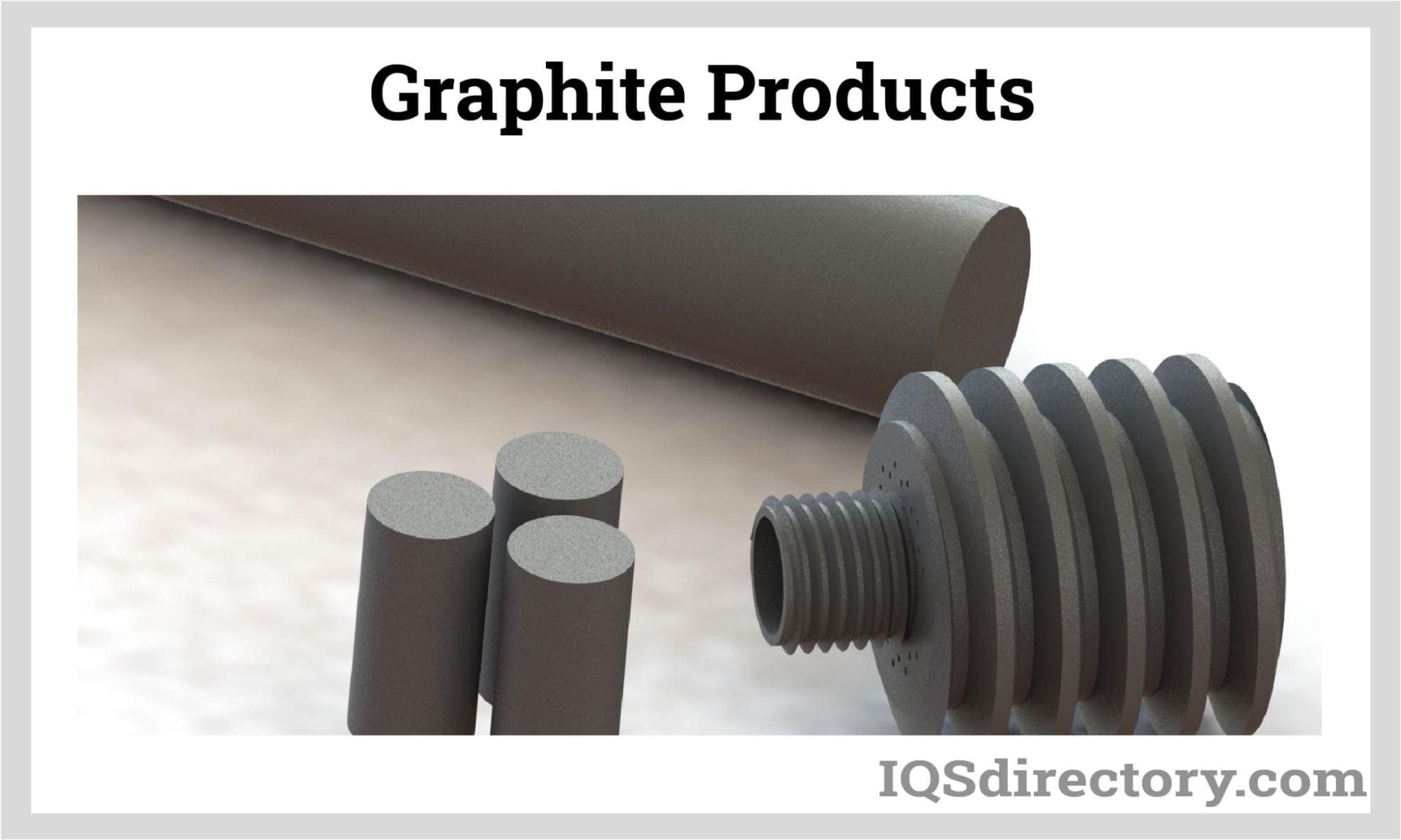

Graphite machining is the process of cutting or shaping graphite material into a desired shape or size. Graphite is a form of carbon that is highly conductive and chemically stable, making it a popular material for a wide range of applications. Graphite machining involves specialized tools and processes that are designed to produce high-quality, precision components with a range of complex geometries. Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

The Precision Machined Products Division of Dynamic Materials Corp. specializes in graphite machining, graphite machine work and graphite components for a variety of industries. We offer high-quality, cost-effective machined graphite in all shapes and sizes.

GraphiteStore.com offers graphite machining for graphite products and parts, including graphite rods, graphite fixtures and cathodic protection anodes. We stock certified grades or can obtain economical imported grades. GraphiteStore.com provides machined graphite to a number of diverse industries and markets.

At Graphite Sales, Inc., we have been at the forefront of the graphite machining industry since 1971, delivering unparalleled expertise and precision in every project we undertake. Our legacy is built on a deep understanding of graphite's unique properties and an unwavering commitment to quality. Over the decades, we have honed our skills and expanded our capabilities, ensuring that we meet the...

More Graphite Machining Companies

Graphite has been used for centuries as a lubricant and drawing material, but it wasn’t until the 1800s that graphite began to be used in industrial applications. In the early 1900s, the development of the electrical industry led to increased demand for graphite products, and graphite machining began to emerge as a specialized field.

Equipment Used for Graphite Machining

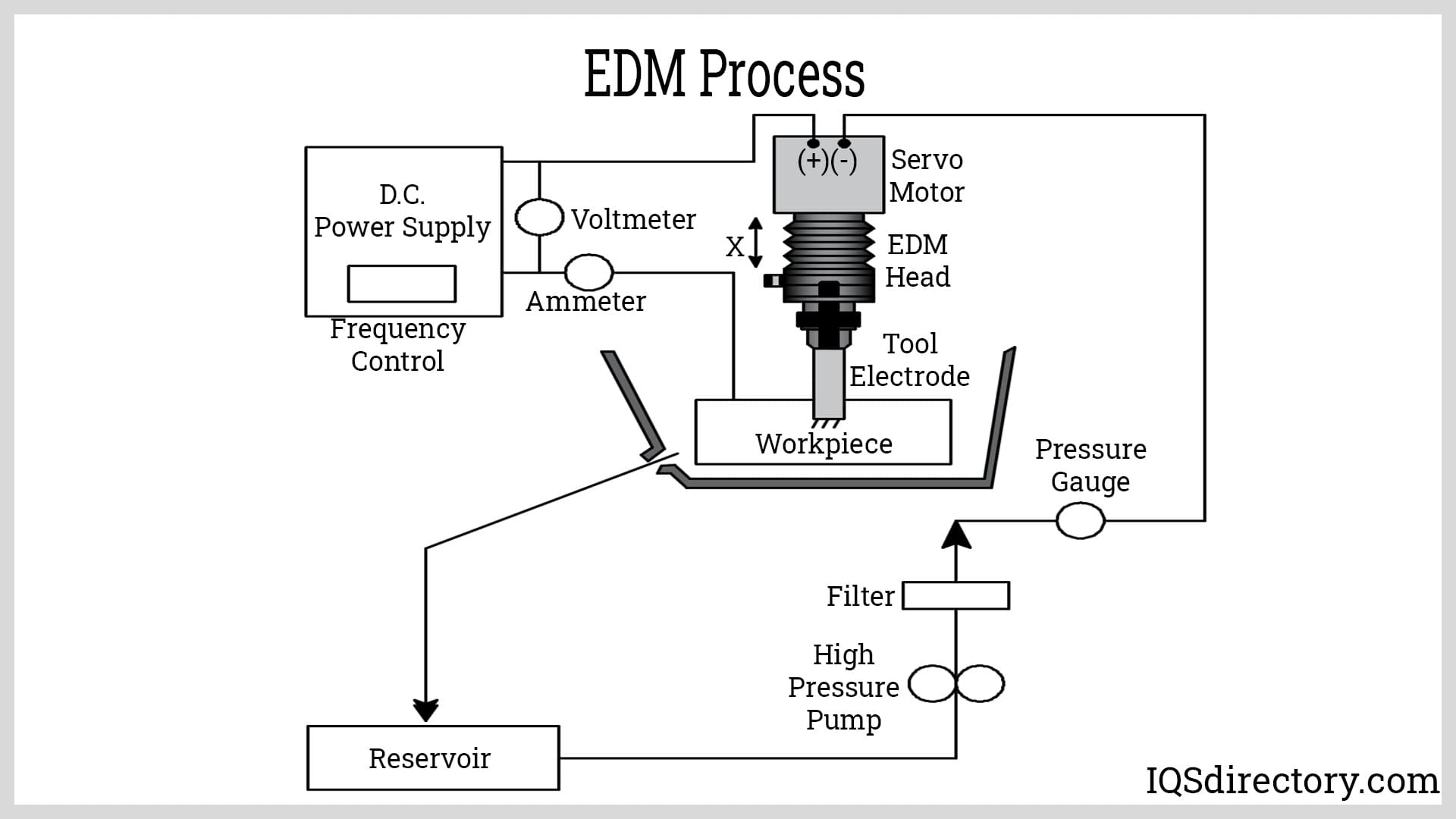

Graphite machining requires specialized equipment due to the unique properties of graphite, which can be brittle and prone to chipping or cracking during machining. The equipment used for graphite machining typically includes high-speed milling machines, CNC (computer numerical control) machines, and EDM machines.

The tools used in graphite machining also need to be carefully selected and maintained to ensure quality and accuracy. For example, graphite machining requires specially designed cutting tools made of high-quality materials that can withstand the high temperatures and pressures involved in machining graphite. In addition, the tools need to be properly maintained and sharpened to prevent chipping and breakage during machining.CNC (computer numerical control) machines are commonly used in graphite machining to ensure precision and accuracy in the machining process.

Graphite Machining Processes

The most common process for graphite machining is milling. Other common processes include turning, drilling, and grinding. Electrical discharge machining (EDM) is also commonly used for graphite machining, especially for intricate or complex shapes. Each of these processes has its own advantages and disadvantages, and the choice of process will depend on the specific requirements of the application. We detail each of these distinctive graphite machining processes below.

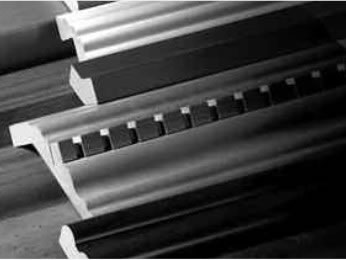

Milling: Milling is the most common process used for graphite machining. It involves the use of a rotating cutting tool, such as an end mill or a face mill, to remove material from the surface of the graphite. Milling is ideal for producing flat or contoured surfaces, as well as pockets or slots in the graphite.

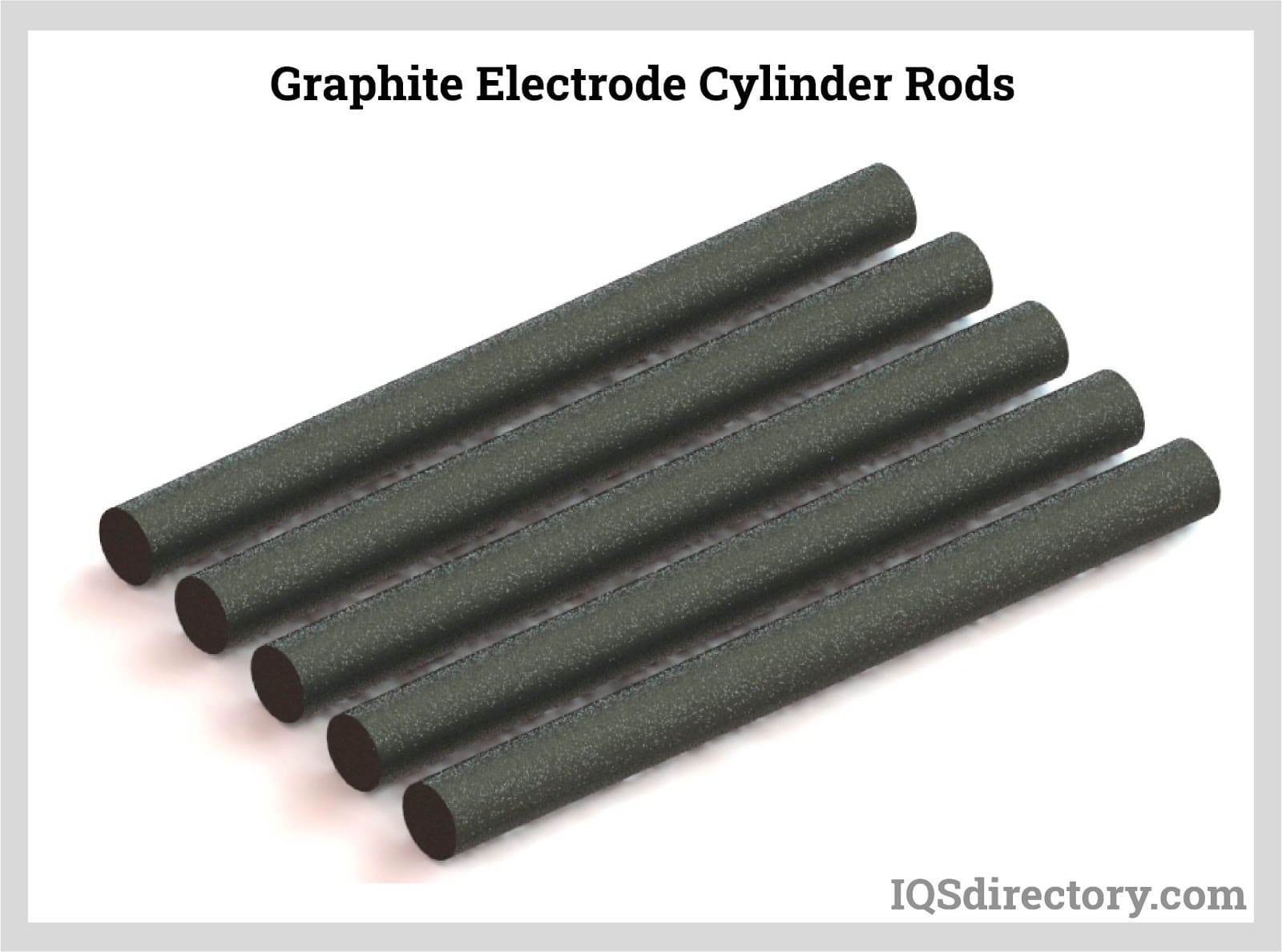

Turning: Turning involves the use of a lathe to rotate the graphite while a cutting tool is used to remove material from the surface. This process is ideal for producing cylindrical shapes, such as rods or tubes.

Drilling: Drilling involves the use of a rotating cutting tool, such as a drill bit, to create holes in the graphite. This process is commonly used for producing holes for fasteners or to create openings for components.

Grinding: Grinding involves the use of an abrasive wheel to remove material from the surface of the graphite. This process is ideal for producing smooth, flat surfaces, and can be used to achieve very tight tolerances.

Electrical Discharge Machining (EDM): EDM involves the use of a series of electrical discharges to remove material from the graphite. This process is ideal for producing highly precise and intricate shapes, and is often used for producing molds or dies for plastic injection molding.

Limitations and Negatives of Graphite Machining

While graphite is a highly useful material, it does have some limitations. Graphite is relatively brittle and can be prone to chipping or cracking during machining. Traditional graphite machining methods such as milling, turning, and drilling can be used to shape graphite, but they can produce significant amounts of dust and require frequent tool changes. Additionally, the dust produced during machining can be hazardous to human health if inhaled. Environmental concerns related to graphite machining include the disposal of used graphite tools and the potential release of graphite dust into the air or water. Advanced methods of graphite machining such as electrical discharge machining (EDM) can produce highly precise and intricate shapes, but can be more expensive and time-consuming.

Benefits of Graphite Machining

Despite these limitations, graphite machining has many benefits that make it a popular choice for a variety of applications. Graphite is a highly stable and chemically resistant material, making it ideal for use in harsh environments. It also has excellent thermal and electrical conductivity properties, making it a popular choice for electronic components and heating elements. Graphite is also relatively lightweight and can be machined to extremely tight tolerances, making it a versatile material for a wide range of applications.

Applications of Graphite Machining

As a result of the aforementioned benefits, graphite machining is used in a variety of industries, including aerospace, automotive, electronics, and manufacturing.

Aerospace Applications

In the aerospace industry, graphite machining is used to produce rocket nozzles and satellite components. Graphite’s ability to withstand high temperatures and harsh environments makes it an ideal material for these applications.

Automotive Applications

In the automotive industry, graphite machining is used to produce EDM electrodes and spark plugs. Graphite’s ability to conduct electricity and resist chemical erosion makes it an ideal material for these applications.

Electronics Applications

In the electronics industry, graphite machining is used to produce semiconductor components and LCD screens. Graphite’s high thermal and electrical conductivity properties make it an ideal material for these applications.

Manufacturing Applications

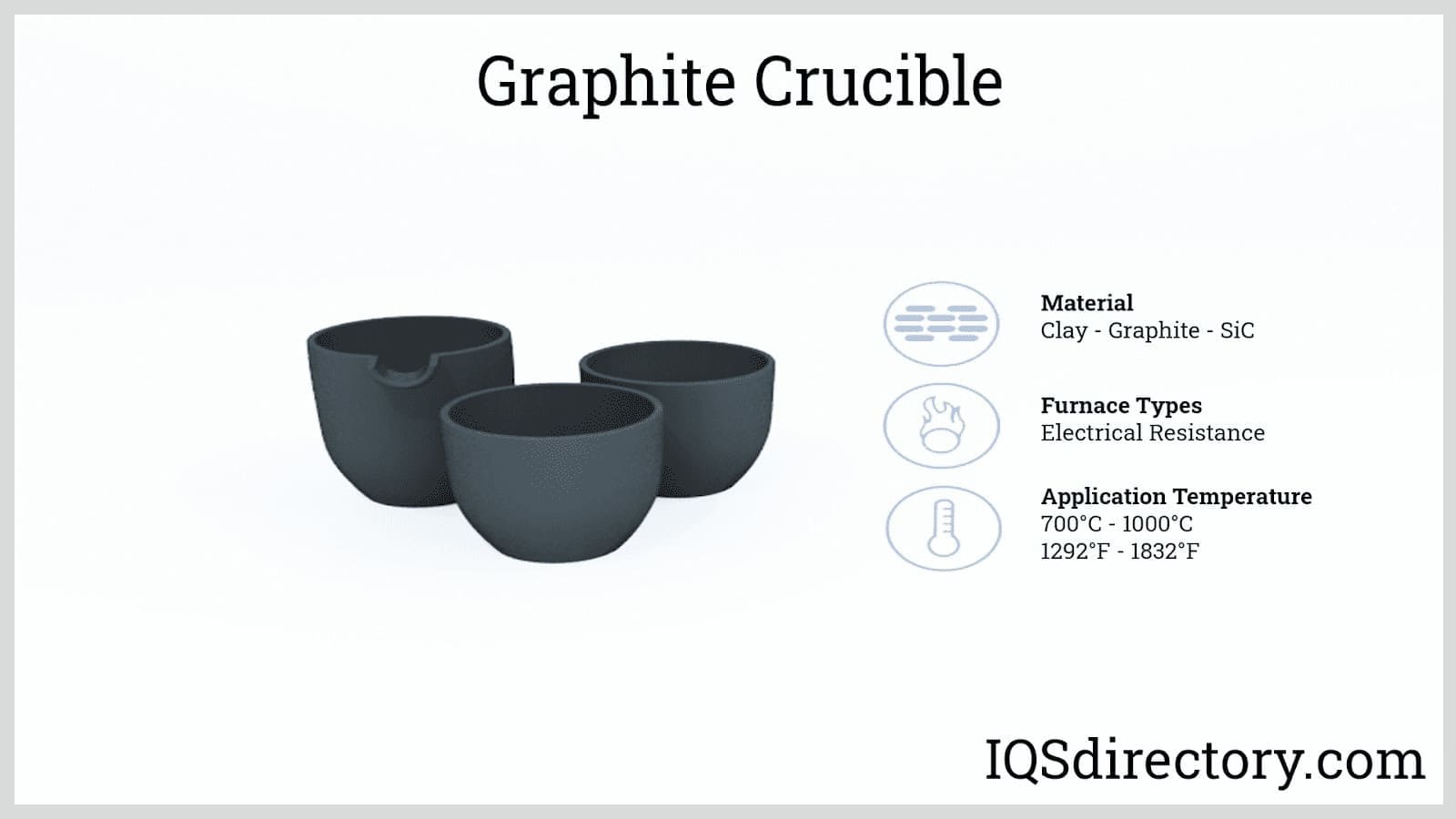

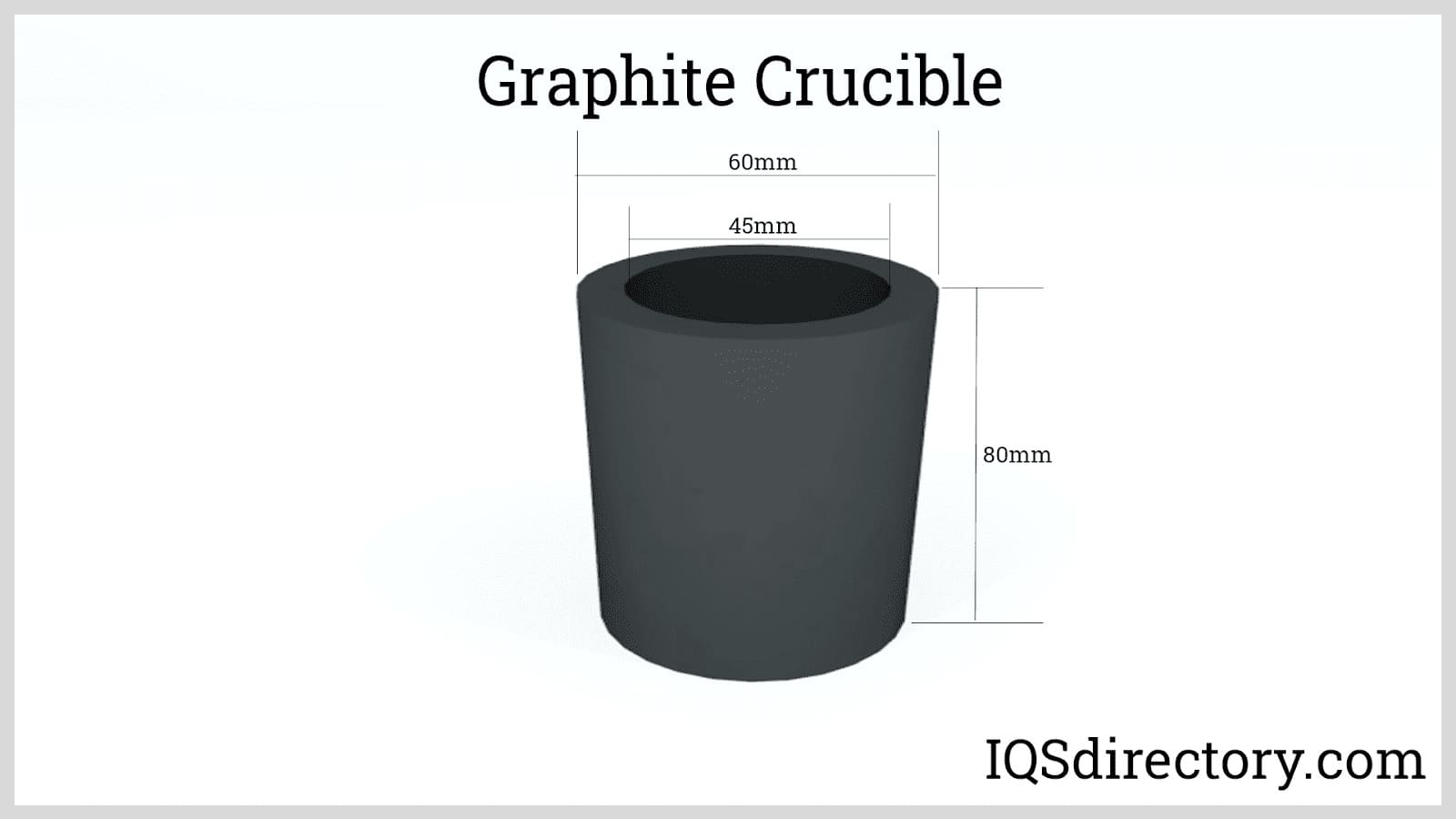

In the manufacturing industry, graphite machining is used to produce molds for plastic injection and crucibles for metal casting. Graphite’s ability to withstand high temperatures and resist chemical erosion makes it an ideal material for these applications.

Choosing the Correct Graphite Machining Company

To ensure you have the most productive outcome when choosing a graphite machining company, it is important to compare several businesses using our directory of graphite machining companies. Each graphite machining company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the business for more information or request a quote. Review each graphite machining company’s website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple graphite machining businesses with the same form.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services