Bearings are simple parts that are used to reduce friction when placed between two moving parts and are often applied with traditional lubricants to decrease friction. However, there are certain situations when lubricants cannot be used and in these instances, bearings made of graphite are used because they are self-lubricating. Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

The Precision Machined Products Division of Dynamic Materials Corp. specializes in graphite machining, graphite machine work and graphite components for a variety of industries. We offer high-quality, cost-effective machined graphite in all shapes and sizes.

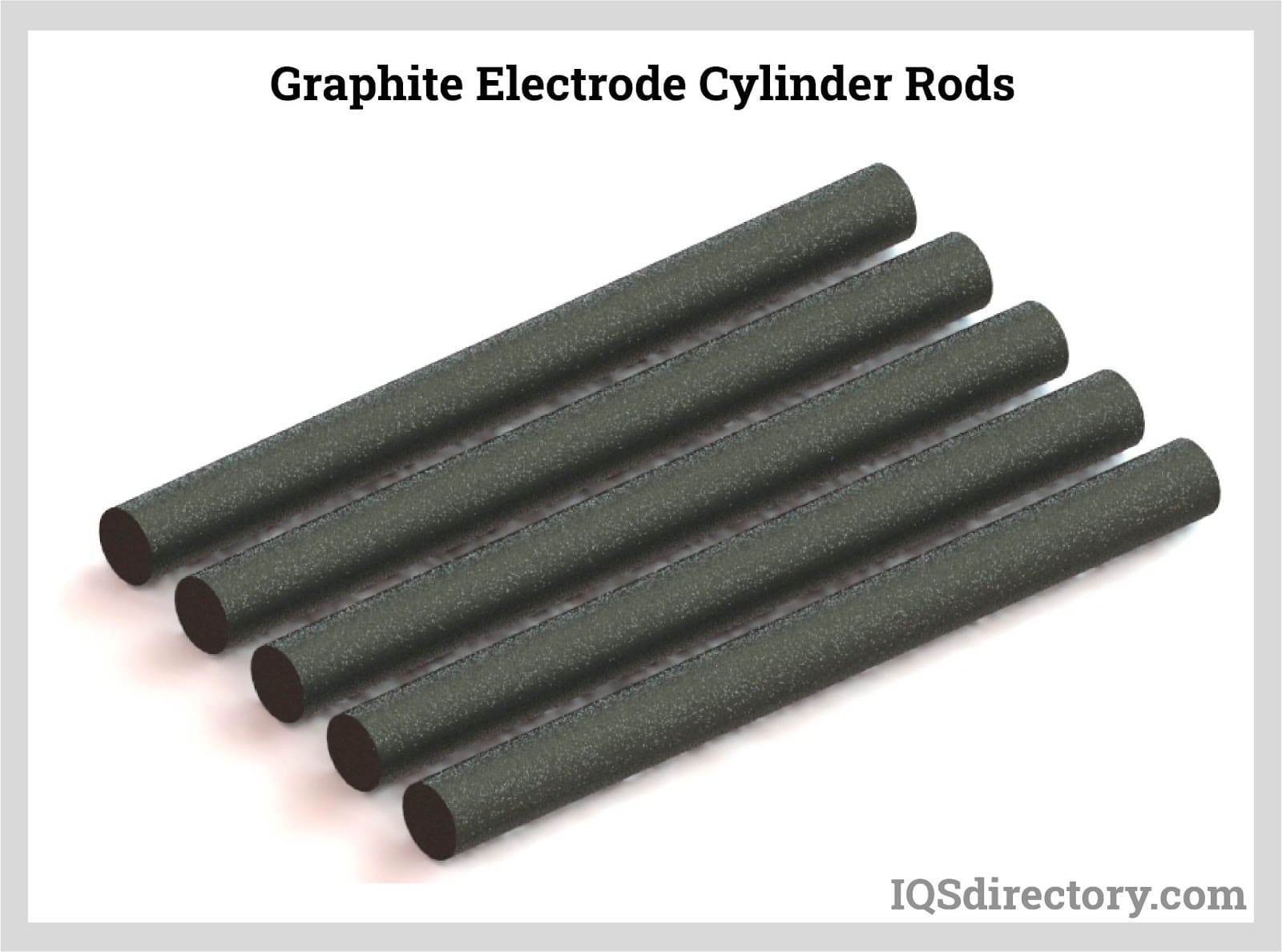

GraphiteStore.com offers graphite machining for graphite products and parts, including graphite rods, graphite fixtures and cathodic protection anodes. We stock certified grades or can obtain economical imported grades. GraphiteStore.com provides machined graphite to a number of diverse industries and markets.

At Graphite Sales, Inc., we have been at the forefront of the graphite machining industry since 1971, delivering unparalleled expertise and precision in every project we undertake. Our legacy is built on a deep understanding of graphite's unique properties and an unwavering commitment to quality. Over the decades, we have honed our skills and expanded our capabilities, ensuring that we meet the...

More Graphite Bearing Companies

Graphite is naturally a greasy mineral, and does not require any additional fluids to reduce friction when used as a bearing. It also has an extreme temperature resistance, more than any metal, and is able to maintain its structure and shape even in temperatures up to 5000°F. Therefore, machined graphite is commonly used in high heat environments, where oil, grease and metals tend to oxidize, often in load capacity systems.

Using graphite bearings dramatically opens up the temperature and chemical range of mechanical operations; some even fare well in cryogenic conditions as graphite is not susceptible to damage as a result of thermal shock. Mostly, they are used in the food, beverage, medical and pharmaceutical industries in machinery where contamination is a concern. They also exhibit high temperature stability and chemical resistance, and can therefore operate in underwater, outer space, underground, in liquid, gas and vacuum environments.

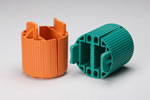

Graphite bearings are able to operate in extreme heat at temperatures significantly higher than any lubricants, which begin to carbonize at temperatures above 200º C. The bearings are fabricated via the extrusion process, which involves heating a mixture of graphite powder and additives until soft and forcing it through a hollow profile.

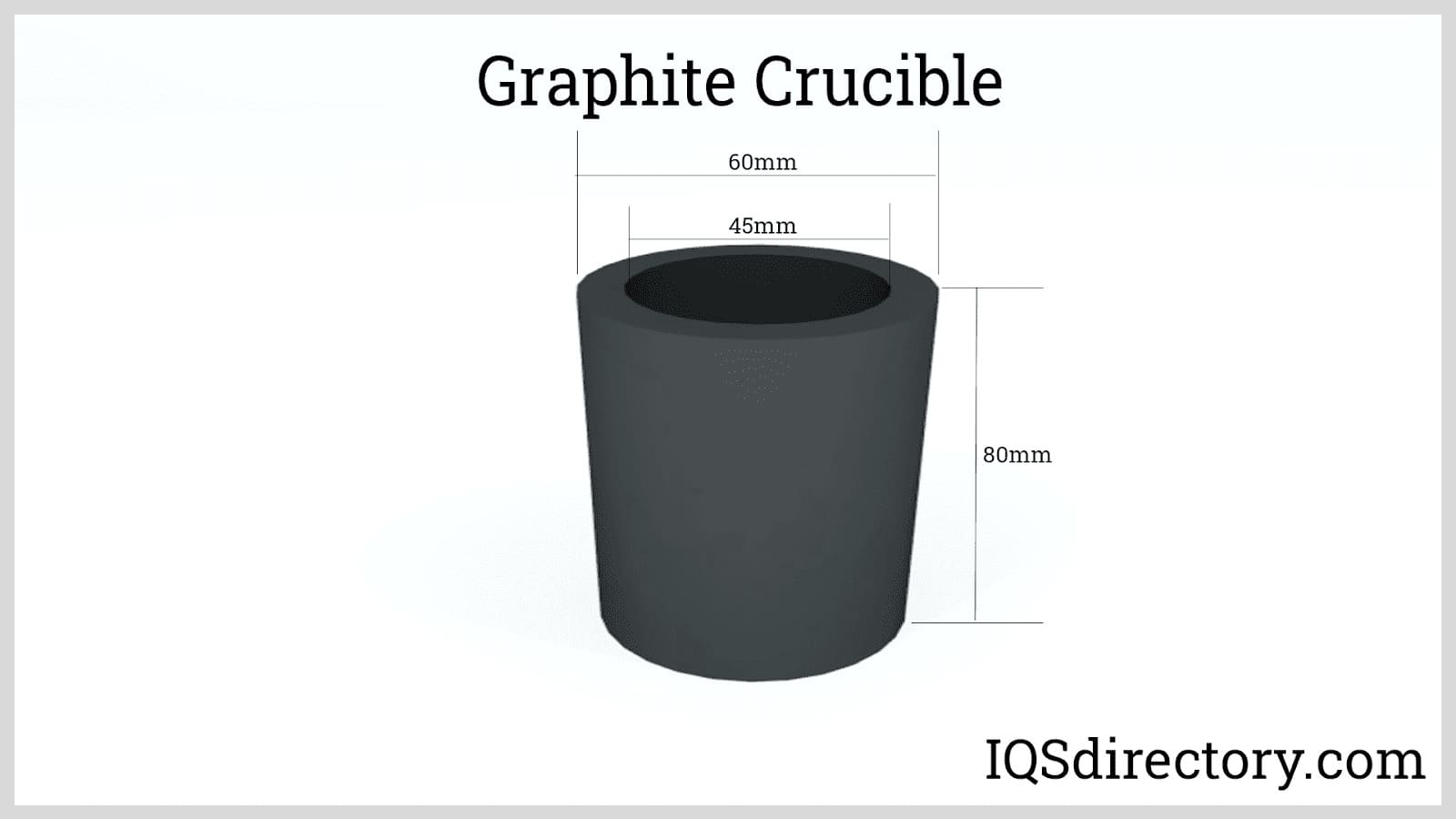

They are generally shaped like standard bushings—round profiles, thin and hollow. Graphite bearings are black or dark grey in color, and are usually smooth and uniform in thickness. Since graphite tends to be a porous material, many bearings are put through post processing secondary operations, where they are impregnated with wax, high purity linseed oil or a resin. This smoothes out the surface of the bearing and prevents any problems that may occur if water or gas seeps into the graphite’s exterior surface.

The wax, resin or oil reduces the porosity of graphite, making it less susceptible to interior wear and tear. Graphite bearings are long lasting, although as with all bearings or load carrying components, will need to be replaced from time to time. Due to these many advantages, including being dimensionally stable, graphite products are used in a large number of corrosive and abrasive applications.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services