The physical properties of graphite make it an ideal choice for this purpose. Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

The Precision Machined Products Division of Dynamic Materials Corp. specializes in graphite machining, graphite machine work and graphite components for a variety of industries. We offer high-quality, cost-effective machined graphite in all shapes and sizes.

GraphiteStore.com offers graphite machining for graphite products and parts, including graphite rods, graphite fixtures and cathodic protection anodes. We stock certified grades or can obtain economical imported grades. GraphiteStore.com provides machined graphite to a number of diverse industries and markets.

At Graphite Sales, Inc., we have been at the forefront of the graphite machining industry since 1971, delivering unparalleled expertise and precision in every project we undertake. Our legacy is built on a deep understanding of graphite's unique properties and an unwavering commitment to quality. Over the decades, we have honed our skills and expanded our capabilities, ensuring that we meet the...

More Graphite Electrode Companies

Steel requires extreme temperatures in order to melt into liquid form to be used in other metal fabrication processes, and graphite is able to conduct electricity at even extremely high temperatures.

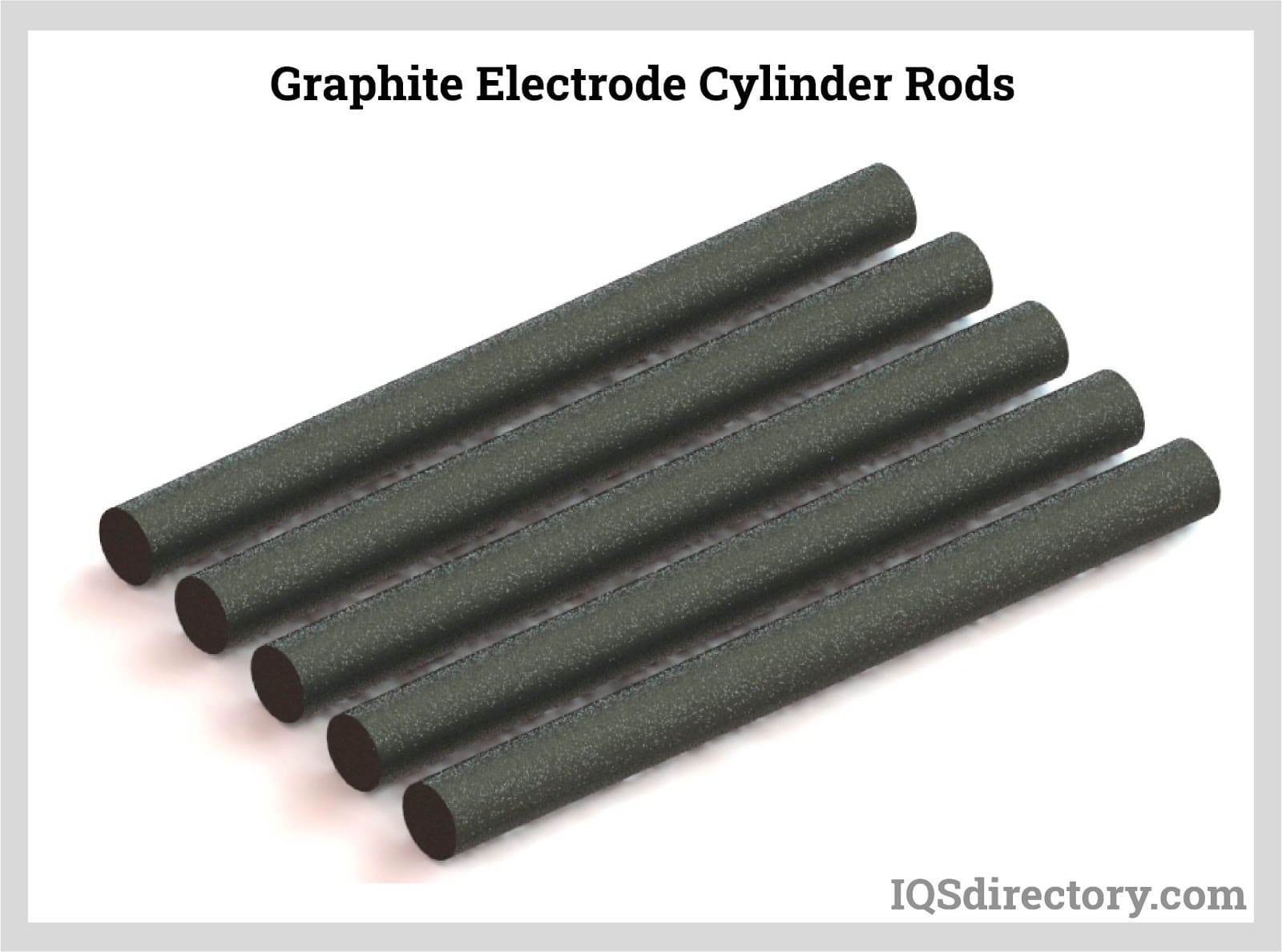

The electric arc furnaces themselves are large containers. The steel scraps for recycling are placed into the container and the roof is lowered. The graphite rods, or electrodes are components of the roof structure of the furnaces and are assembled into columns and attached to the roof. Depending on the manufacturer, the electrodes can be as small as 3 inches in diameter, or as large as 30 inches. This will also be dependent on the size of the furnace and the volume of material requiring melting.

The electrodes will reach up to 5000°F, half the temperature of the surface of the sun and therefore machined graphite must be used as it is the only material that can withstand such high temperatures and maintain its shape and structure, as well as continue to conduct electricity. The electrodes are attached to an electrical source and in turn generate that energy into heat.

Graphite electrodes are typically coated with siloxane fluid which is able to reduce oxidation at extreme temperatures. The different specifics of graphite electrodes are chosen based on various application considerations such as furnace design, power level, fume control system, scrap requirements and charging practice. These factors will help to determine the particle size, shape and length of the graphite electrodes.

Electrodes are typically formed using an extrusion process in order to maintain material integrity and form the desired length and shape. After the steel has melted as a result of the extreme temperatures, it is drained into vats and moved quickly to metal fabrication processes to be made into new metal products. Further uses for graphite electrodes include refining steel in ladle furnaces, smelting processes and for removing defects in castings and weldings.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services