It is important that the current keep flowing, but it does not need to achieve a certain rate or level. Therefore, even though graphite is a resistive material, it is highly ideal in these situations. Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

The Precision Machined Products Division of Dynamic Materials Corp. specializes in graphite machining, graphite machine work and graphite components for a variety of industries. We offer high-quality, cost-effective machined graphite in all shapes and sizes.

GraphiteStore.com offers graphite machining for graphite products and parts, including graphite rods, graphite fixtures and cathodic protection anodes. We stock certified grades or can obtain economical imported grades. GraphiteStore.com provides machined graphite to a number of diverse industries and markets.

At Graphite Sales, Inc., we have been at the forefront of the graphite machining industry since 1971, delivering unparalleled expertise and precision in every project we undertake. Our legacy is built on a deep understanding of graphite's unique properties and an unwavering commitment to quality. Over the decades, we have honed our skills and expanded our capabilities, ensuring that we meet the...

More Graphite Anode Companies

The anodes are usually constructed from a combination of petroleum coke and coal tar pitch and are relatively easy to machine as finish or appearance is also not a determining factor in effectiveness. Used conjunctively with carbon graphite or other anode backfill, graphite anodes provide a long lasting solution and are one of the most commonly recycled graphite products as they contain few additives.

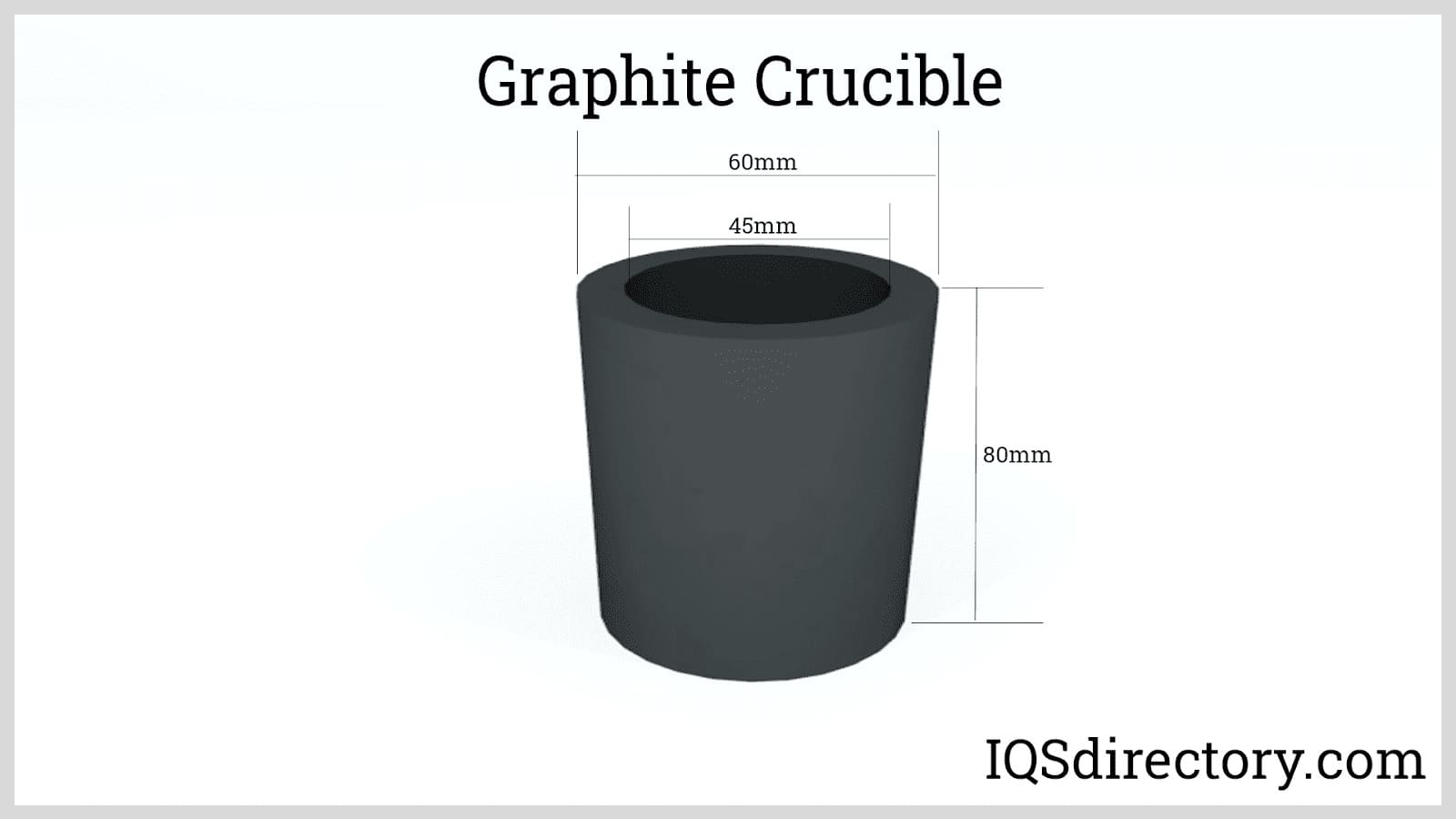

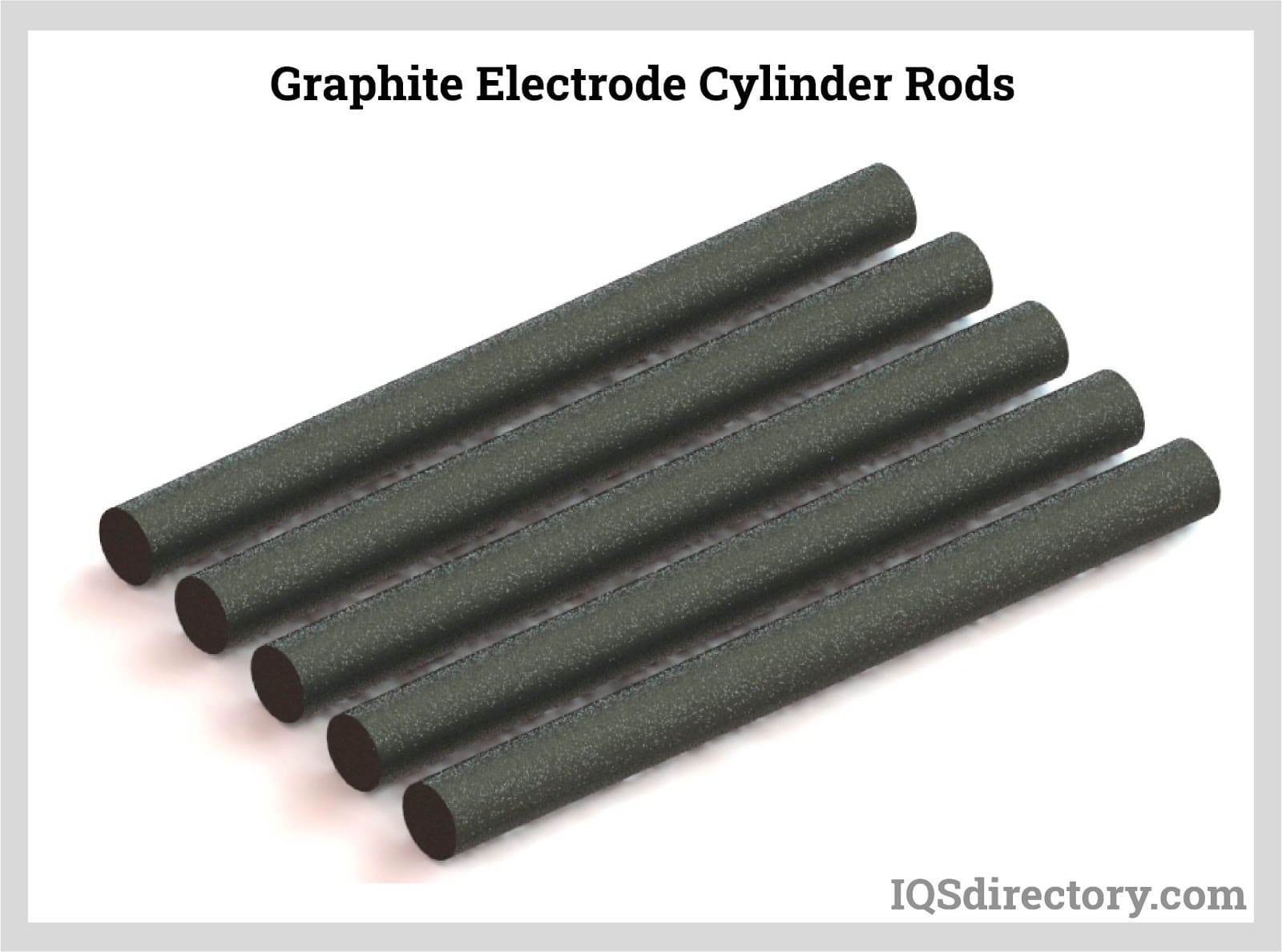

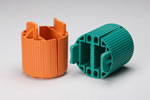

Custom specifications are often used to produce graphite anodes as they are typically application specific. Common approximate sizes are between 60 and 150mm in diameter and from 1200 to 1500mm long. The extruded graphite rods are baked in an oven and sintered to improve the density of graphite. They are typically extruded around a thin brass pin which is then connected to a cable in order to form the electrochemical cell necessary for the process of cathodic protection.

Over time however, despite its durability and corrosion resistance, graphite will begin to break down, especially when used in the purpose of cathodic protection. However, some graphite anodes are treated with a non-porous quality non-conducting material such as oils, microcrystalline waxes or resins. The treatment of graphite anodes will ensure a higher level of performance, especially in wetter environments when exposure to moisture is prolonged or constant.

The wax, resin or oil seals the porosity of the anode and protects it against water absorption as well as improving the stability and wear rate by reducing the electrochemical reactions within the anode. Applications such as dock-side uses and water tanks, as well as deep underground installations are recommended to pre-treat the anodes to ensure optimal performance.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services