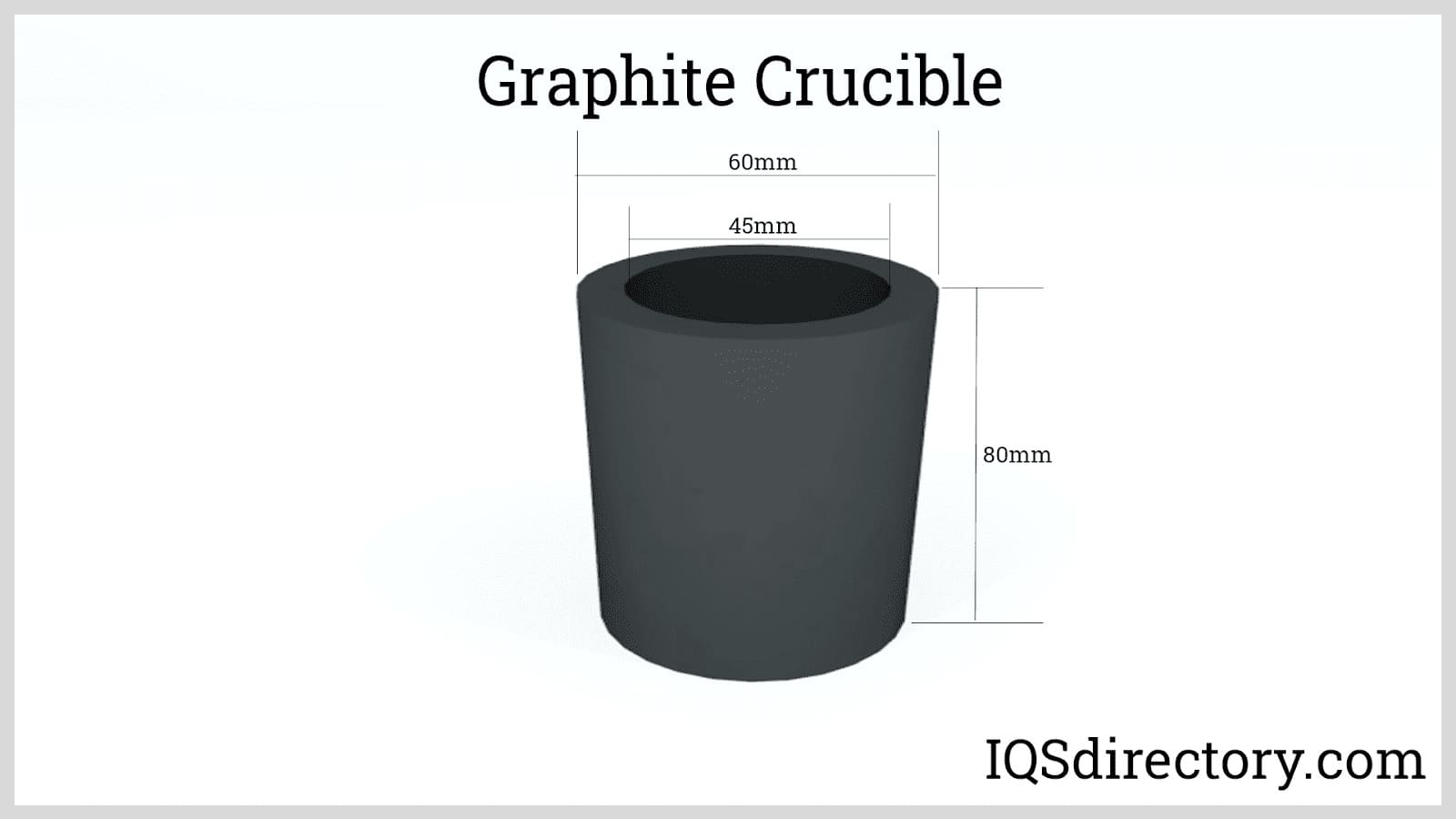

The reason why graphite molds are utilized in this form of manufacturing is due to the fact that graphite as a material has a rather high melting point of 4200 K or around 6,422 degrees Fahrenheit. Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

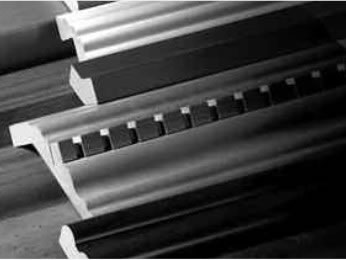

The Precision Machined Products Division of Dynamic Materials Corp. specializes in graphite machining, graphite machine work and graphite components for a variety of industries. We offer high-quality, cost-effective machined graphite in all shapes and sizes.

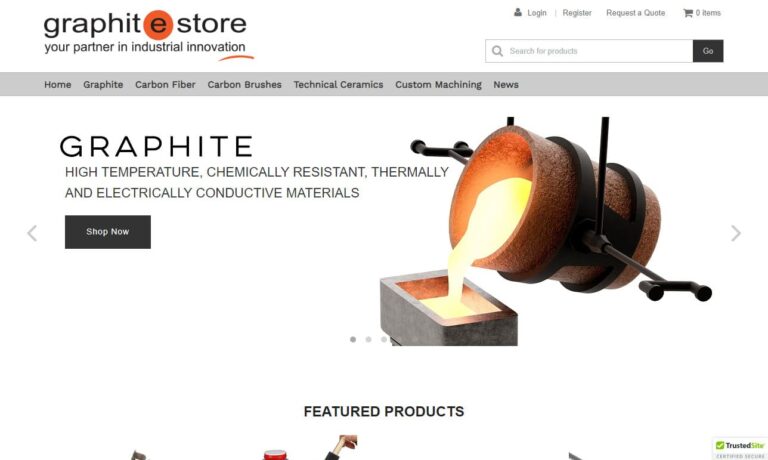

GraphiteStore.com offers graphite machining for graphite products and parts, including graphite rods, graphite fixtures and cathodic protection anodes. We stock certified grades or can obtain economical imported grades. GraphiteStore.com provides machined graphite to a number of diverse industries and markets.

At Graphite Sales, Inc., we have been at the forefront of the graphite machining industry since 1971, delivering unparalleled expertise and precision in every project we undertake. Our legacy is built on a deep understanding of graphite's unique properties and an unwavering commitment to quality. Over the decades, we have honed our skills and expanded our capabilities, ensuring that we meet the...

More Graphite Mold Companies

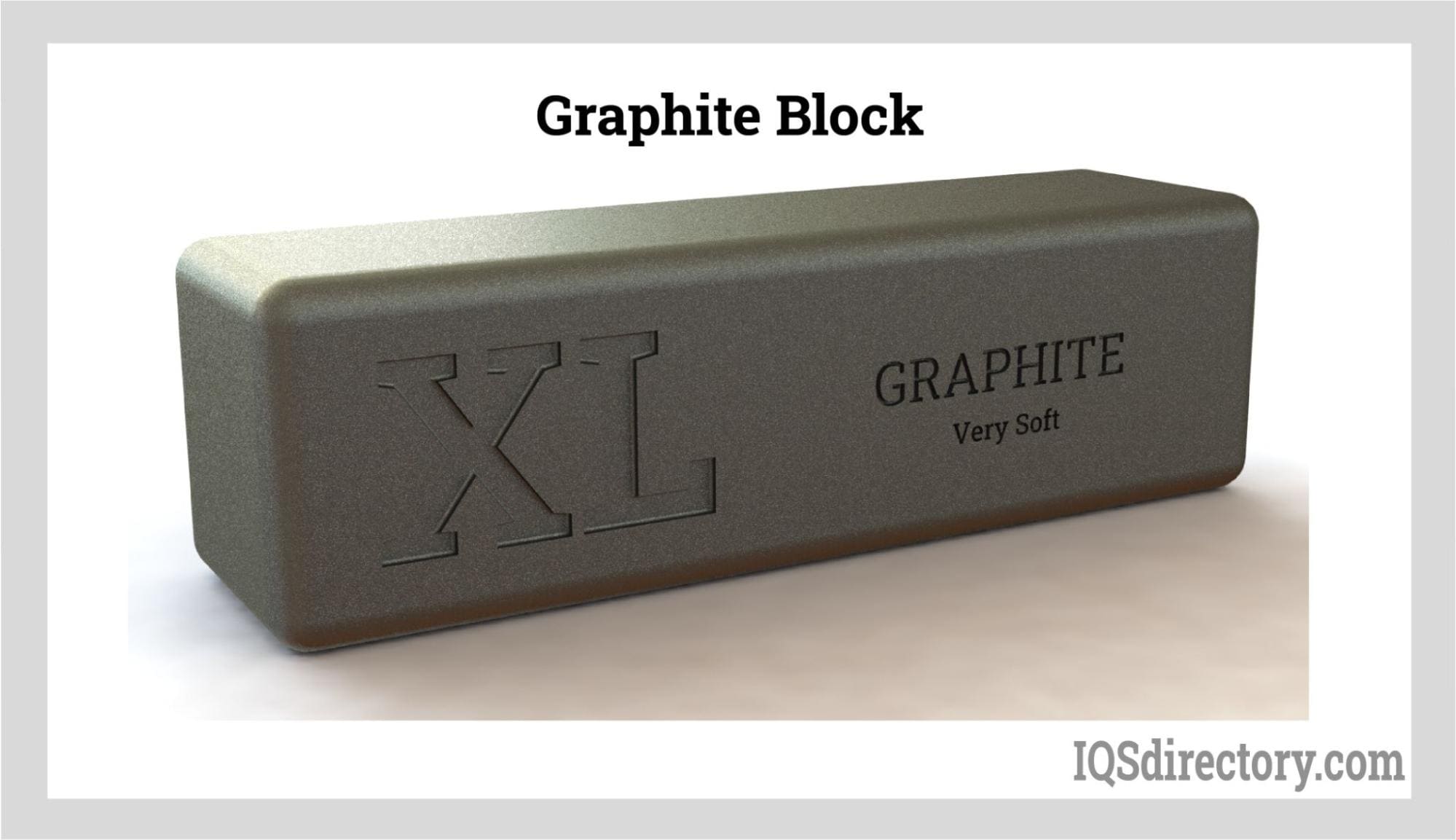

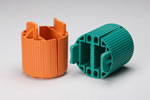

This high melting point is important as the molds are typically filled with materials that are in a molten state, meaning the molds must be able to withstand high temperatures which melt other materials. A graphite mold is typically made from two-pieces which fit together tightly with an opening towards the top where the molten material of your choice can be poured into once the mold is filled the material is allowed to cool which results in a final product or a product that is ready for secondary finishing steps.

Finding the right graphite manufacturer can be harder than it seems, as you will typically have to search through manufacturers who do this type of permanent molding in order to receive a product that fits your needs and the requirements of your application. A well-made graphite mold is the first step to making the perfect final product; a poorly constructed graphite mold means that the final product may have some flaws or imperfection that may impact the final application of that product.

There are a number of different ways in which graphite molds are utilized from gravity filling by simply pouring in a molten material which is the simplest and typically most cost effective method, to a more in-depth process such as pressure based filling of the mold in order to preserve the finer details within the mold. This process takes a bit longer and cost a bit more, but results in a more detailed and specific final product.

Whatever your final application or desired final product is, is what dictates what type of graphite mold process is used by the manufacturer of your choice. It is important to relay the specifications and requirements of your application to the mold manufacturer so they can construct a graphite mold that will fit all of your needs and wants.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services