Graphite is also a chemically inert substance and has an extreme temperature resistance. Because of these unique properties, graphite outperforms almost every other material, including steel and titanium, in plate applications that require very high temperatures. Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

The Precision Machined Products Division of Dynamic Materials Corp. specializes in graphite machining, graphite machine work and graphite components for a variety of industries. We offer high-quality, cost-effective machined graphite in all shapes and sizes.

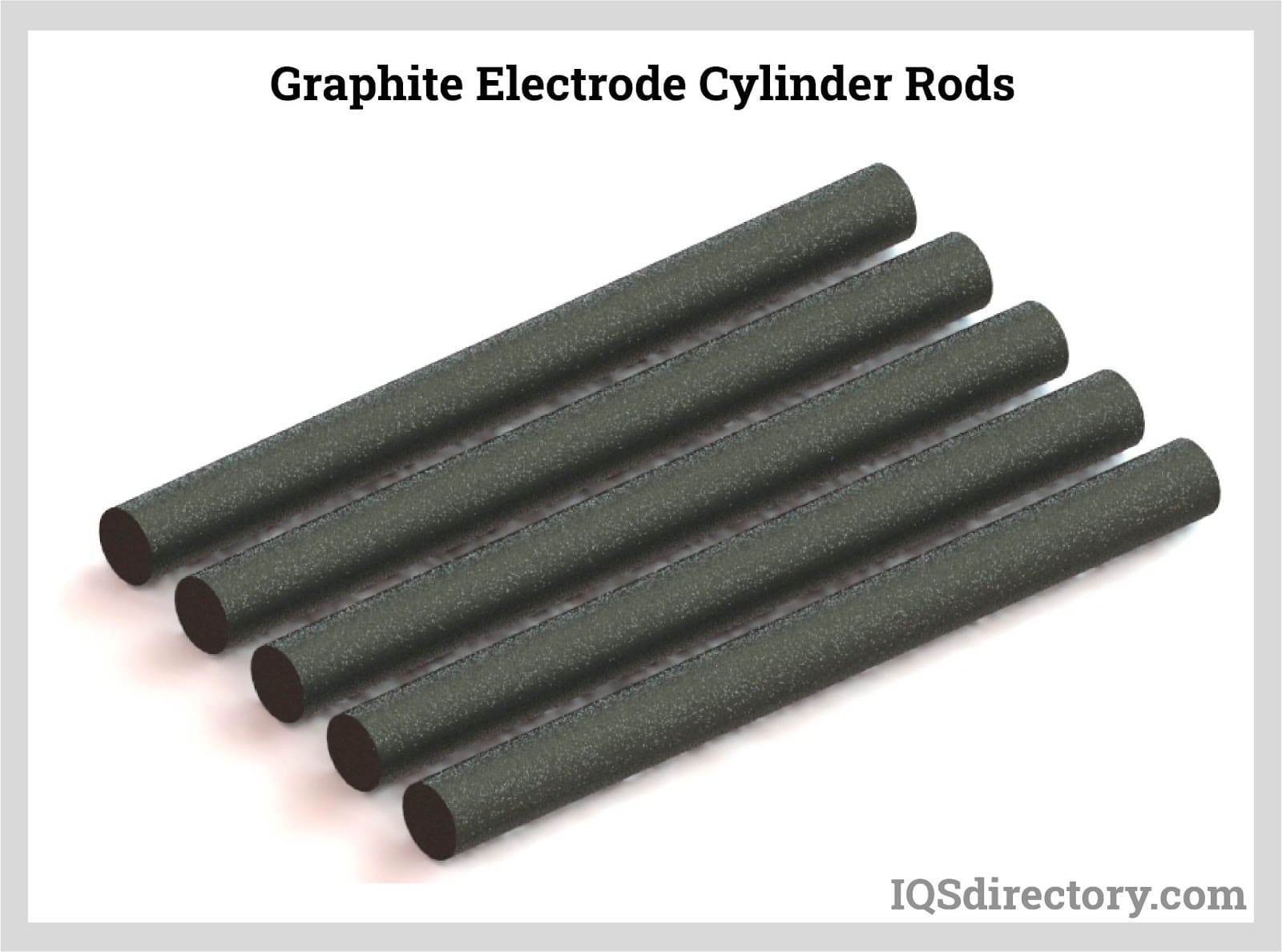

GraphiteStore.com offers graphite machining for graphite products and parts, including graphite rods, graphite fixtures and cathodic protection anodes. We stock certified grades or can obtain economical imported grades. GraphiteStore.com provides machined graphite to a number of diverse industries and markets.

At Graphite Sales, Inc., we have been at the forefront of the graphite machining industry since 1971, delivering unparalleled expertise and precision in every project we undertake. Our legacy is built on a deep understanding of graphite's unique properties and an unwavering commitment to quality. Over the decades, we have honed our skills and expanded our capabilities, ensuring that we meet the...

More Graphite Plate Companies

Graphite plates are commonly used for structural ribs, components of kilns and copper, zinc and aluminum extrusion machines, cable manufacturing, carbide, electrodes, plastic injection molding parts, lubricating and sealing plates, and the most widely used—bipolar fuel cell construction. They can also be used to dam molten metal in metal fabrication plants and provide a protective barrier in welding processes.

The aerospace, paper, chemical, cement, electronic and electric industries also use graphite plates for many different application functions. Natural graphite is composed of layers of graphite which are not tightly bonded to each other and therefore can be separated easily. Some thinner flexible graphite plates are used as sealing material.

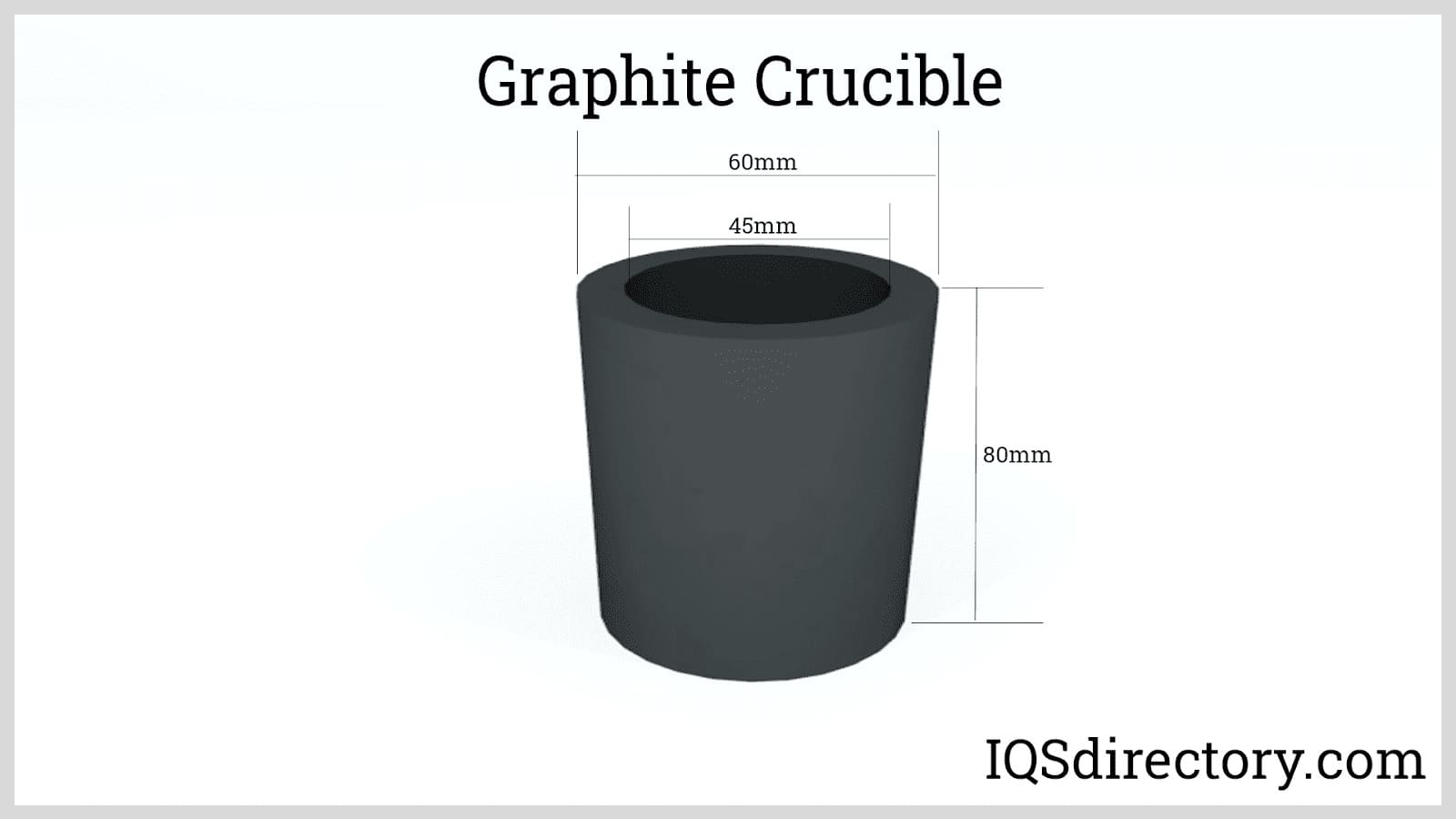

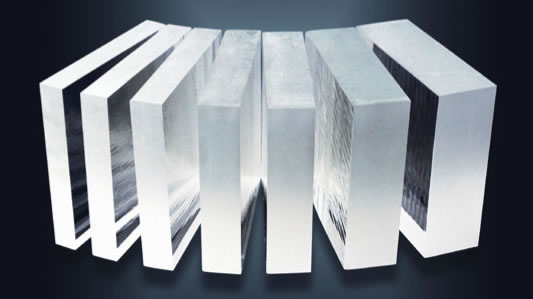

The graphite plates are custom made and also come in many different standard shapes and sizes, although plates are always uniformly flat, generally have 90º angled corners and are thinner than graphite sheets, which are very flexible and are able to be rolled up.

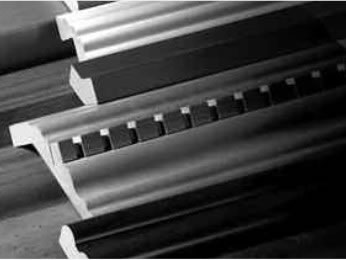

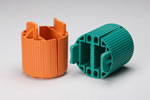

The extrusion process involves pure graphite, carbon graphite or a mixture of materials being heated until flexible and then forced through a hollow profile. Most plates are made of multiple uni-directional layers that have been sandwiched together with an epoxy. Because graphite tends to be a porous material, many plates are impregnated with wax, resin or high purity linseed oil to create a gas-tight seal and eliminate the problems that pores and impurities create.

Many different grades of graphite are used to make plates. IPG is made of fine particles, exhibits high strength and sharp detail. PL-850 is dense and oxidation resistant, meaning it fares will in extremely high temperatures. PL-800 is easy to machine and is also used in high temperature applications like furnaces and kilns.

Pure graphite is used in fuel cells and as graphite electrodes because it has lower density than other temperature resistant metal plates. However, it tends to be quite brittle and polymer binders are added to give the graphite more flexibility. The plates may be smooth, textured, have exterior layers made of high gloss woven carbon fabric, corrugated, engraved or have a patterned design. Like most graphite products, plates are inexpensive and simple to manufacture.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services