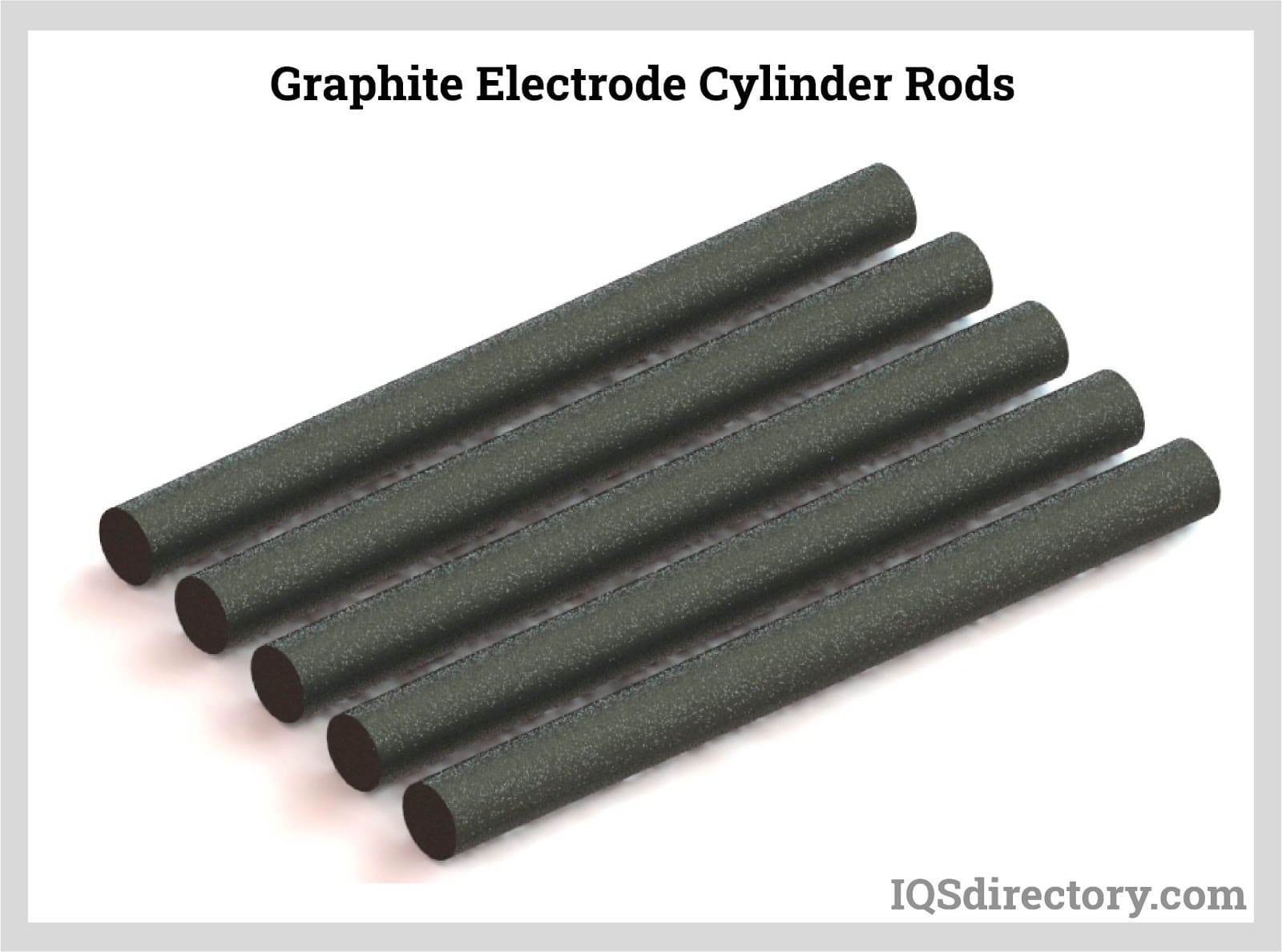

Rods are short, slender, straight objects composed of plastic, metal, ceramic, or organic material. Depending on their size and composition, they can perform several tasks and are quite easy to manufacture. Graphite rods are a particular type made from machined graphite or graphite compounds. They have a well-deserved reputation for having exceptional heat resistance, strong corrosion resistance, non-reactivity, and the capacity to age well (because graphite is a non-fatiguing material). Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

The Precision Machined Products Division of Dynamic Materials Corp. specializes in graphite machining, graphite machine work and graphite components for a variety of industries. We offer high-quality, cost-effective machined graphite in all shapes and sizes.

GraphiteStore.com offers graphite machining for graphite products and parts, including graphite rods, graphite fixtures and cathodic protection anodes. We stock certified grades or can obtain economical imported grades. GraphiteStore.com provides machined graphite to a number of diverse industries and markets.

We provide superior solutions for customers with unique technology, special talents, and one-of-a-kind processes. Our solutions keep customers coming back time after time and our company longevity attests to the effectiveness of our processes. For all graphite machining needs, we can provide solutions to make your business better. Call or visit us online today for more information!

More Graphite Rod Companies

How Graphite is Made

Carbon atoms are arranged in graphite layers, giving them distinctive properties. Though mined worldwide, most natural graphite is found in China, Brazil, Canada, and Madagascar. It is produced when carbon in the earth's crust is subjected to intense pressure and heat, and it is common in metamorphic and igneous rocks. High-purity carbon is included in synthetic graphite, which is also resistant to corrosion and high temperatures. The main components utilized in the production of synthetic graphite are calcined petroleum coke and coal tar pitch, both of which contain graphitizable carbon. The mixture materials are mixed, heated, molded, and baked throughout the manufacturing process.

How Graphite Rods are Made

Molding by Compression

A substance is softened and then pressed to take the shape of the mold in which it is lying during the compression molding process. Before being inserted into an open, heated mold or hole, the material to be molded is first preheated. Next, the mold is sealed from the top while a plug member compresses as it softens. Finally, due to the impacts of pressure and heat, the graphite material spreads out and adopts the shape of the mold.

Preheating Mold

Before loading the mold, the mold must first be prepared. Typical preparation methods include:

- Cleaning the mold.

- Applying a release agent.

- Heating the mold to increase the viscosity of the charge.

Preparing Charges

A variety of materials can be compressed and molded. As a result, they are available in various compositions, sizes, shapes, and packaging. The material is prepared from its delivery state into one better suited for compression. Unpacking, cleaning, cutting, sizing, weighing, and heating are all steps in preparing a charge.

Loading of Charges

The loading of charges requires applying the charge to the lowest part of the mold. The best compression outcome is assured in this method. Afterward, the charge is applied to the mold in the necessary pattern, considering the mold's shape, the necessary thickness, and other factors.

Compression of Rod

Relative motion is produced to bring the two halves of the mold as near together as feasible. As the components draw closer together, the charge is compressed. Compression can force the charge into the mold's cavity to the planned volume. Additionally, it aids curing and guarantees that the product has the right density.

Curing in the Process of Molding

The compressed charge helps harden the end product during this molding process step. It is necessary to lower the temperature or add hardening agents and catalysts to permit setting and hardening. Some of the treatment types are the addition type and condensation type.

Mold Cooling

The mold will be at the ideal temperature for following molding cycles thanks to cooling. But, first, it's crucial to ensure the mold develops the desired thermal and mechanical qualities for removal, use, or storage.

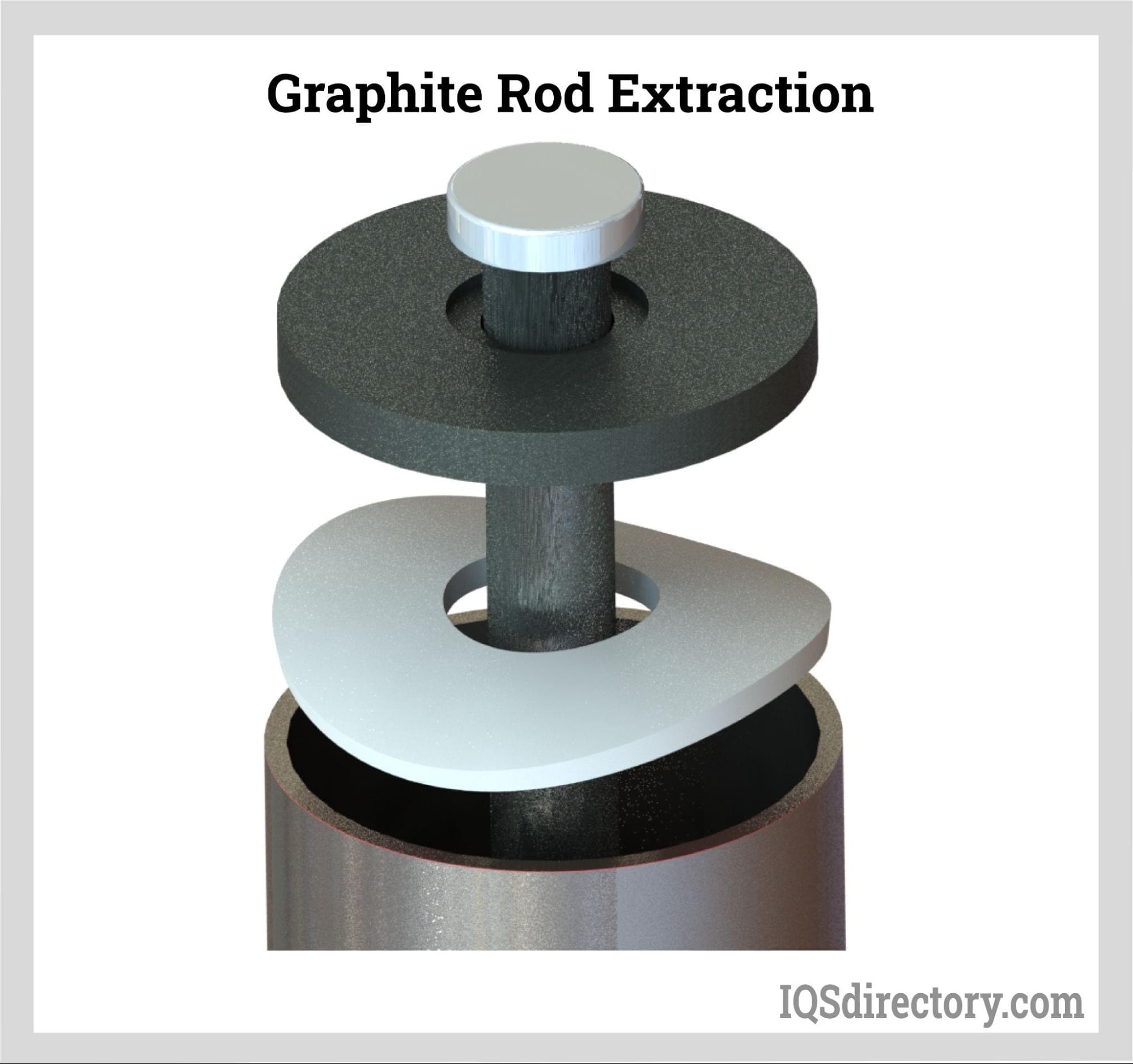

Carbon Ejection

Ejection is the graphite's release from the cure. Automated ejection frequently employs a separate system of suckers or a plunger that moves from the bottom of the mold when ejection is required. To facilitate ejection and avoid product adhesion to the mold, releasing agents and coatings are usually applied to the mold before ejection.

Extrusion of Rod

The conventional extrusion molding method is all that the process of rod extrusion does. This procedure starts with gathering the graphite stock and any necessary additions in a hopper and melting them there. Next, the stock is forced through a tube-shaped die when molten (or liquid). Finally, the stock adopts the size and form of the die after cooling. Once it has cooled, a solid shape can be removed from the die.

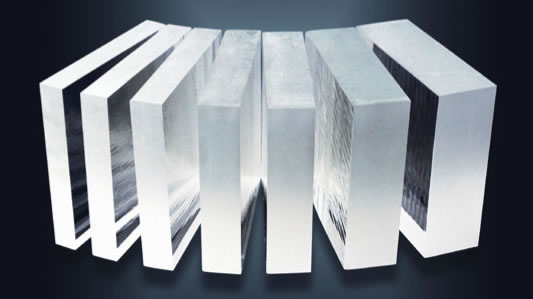

Isostatic Pressing

A forming technique called isostatic pressing uses pressure from all directions. First, the graphite substance is put within a high-pressure confinement vessel to begin working. Next, the containment vessel is pressurized with an inert gas, such as argon. Finally, the vessel is heated after the graphite has been added, increasing the pressure and causing the graphite to develop this way.

What a Graphite Rod Does

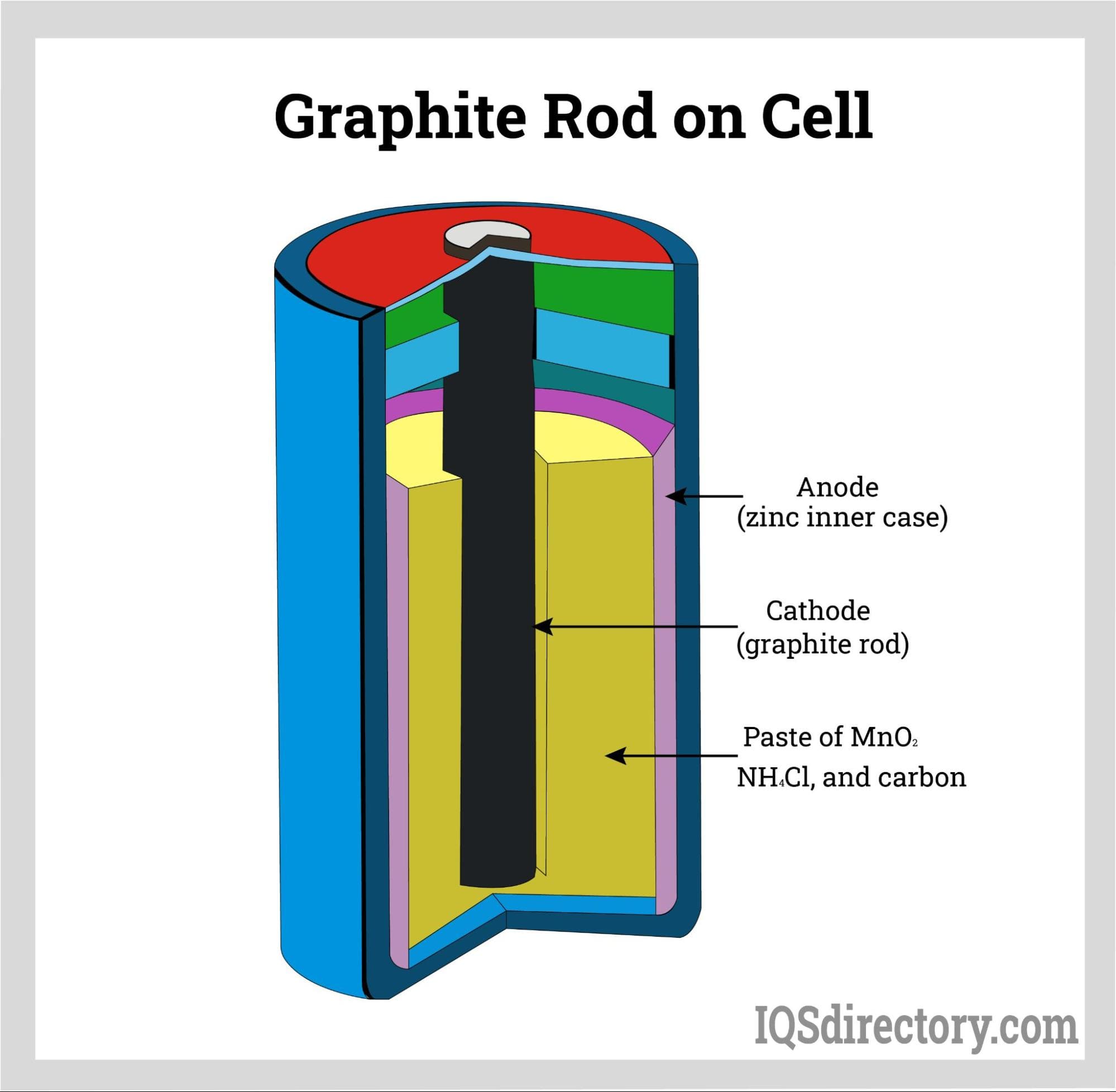

A graphite rod can be used as a flaring tool because of its longevity and strength. The same qualities also allow it to serve as support posts. They serve as stir sticks and electrodes in laboratories. Anode and DCFC fuel are two more frequent uses.

Graphite Rod Applications

For applications that need sensitivity and precision, such as fiber optics and semiconductors, graphite rods are frequently used. Fishing rods and tiny fishing rods are two of the more prevalent uses for graphite rods (since graphite is sensitive, durable, and lightweight).

Because graphite can tolerate extremely high temperatures, heat treatment is utilized in industrial applications to support beams or hearth rails to facilitate thermal expansion. In addition, graphite rods are employed in electrolysis, and the abundance of delocalized electrons makes it possible for electricity to pass through graphite quickly.

Choosing the Right Graphite Rod Manufacturer

To ensure you have the most constructive outcome when purchasing graphite rods from a graphite rod manufacturer, it is important to compare several companies using our directory of graphite rod manufacturers. Each graphite rod manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each graphite rod business manufacturer’s website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple graphite rod manufacturers with the same form.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services