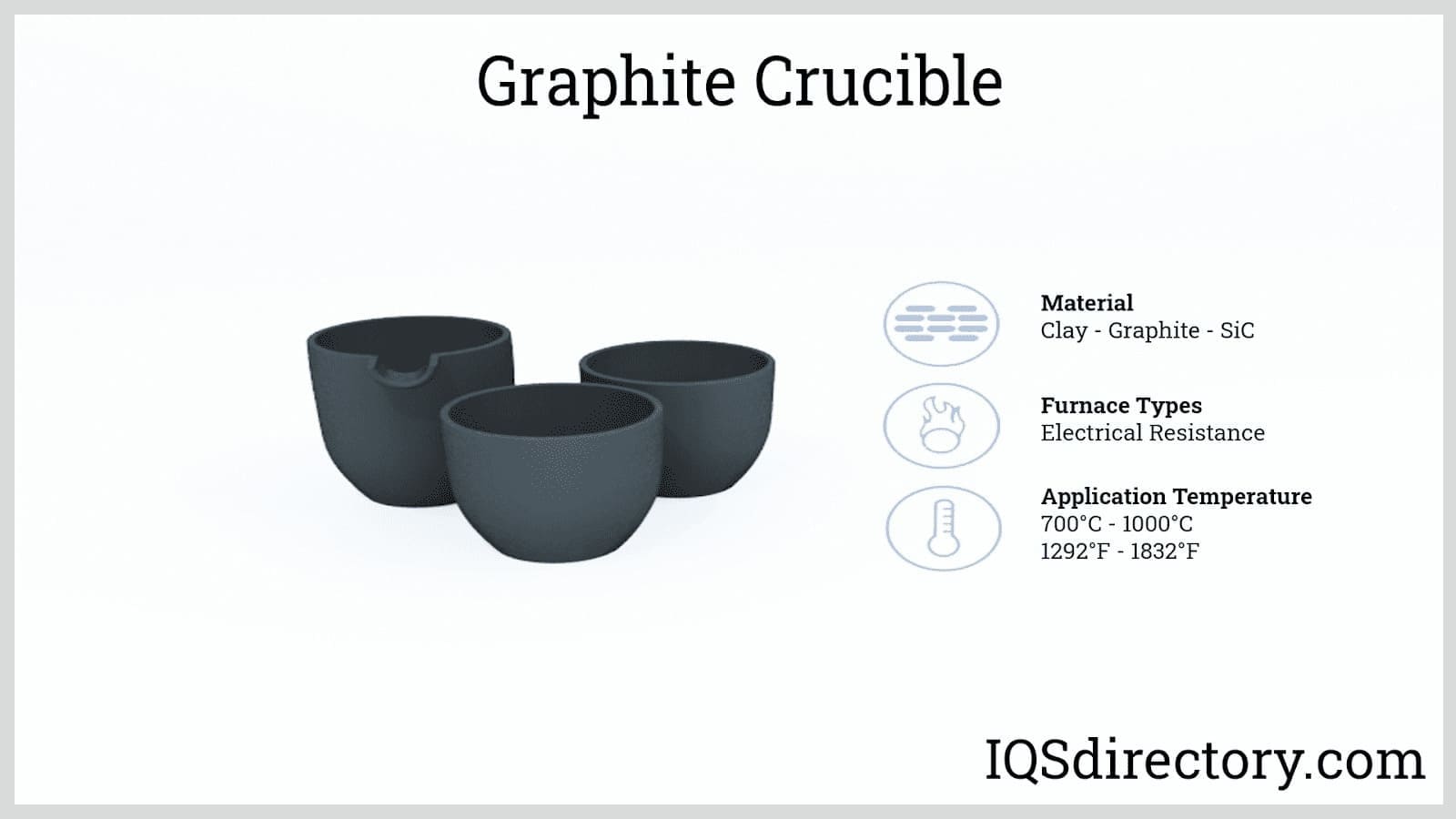

Graphite, a kind of carbon, is frequently used to create crucibles. A graphite crucible is commonly employed to melt non-ferrous or non-iron metals like gold, silver, aluminum, or brass because it endures high temperatures and reacts little with molten metals. Graphite and clay are commonly combined to create graphite crucibles, which are molded and solidified under intense heat. Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

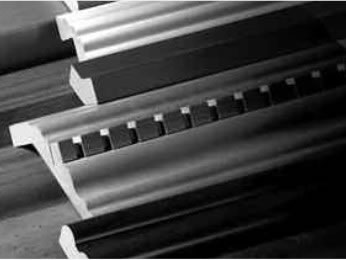

The Precision Machined Products Division of Dynamic Materials Corp. specializes in graphite machining, graphite machine work and graphite components for a variety of industries. We offer high-quality, cost-effective machined graphite in all shapes and sizes.

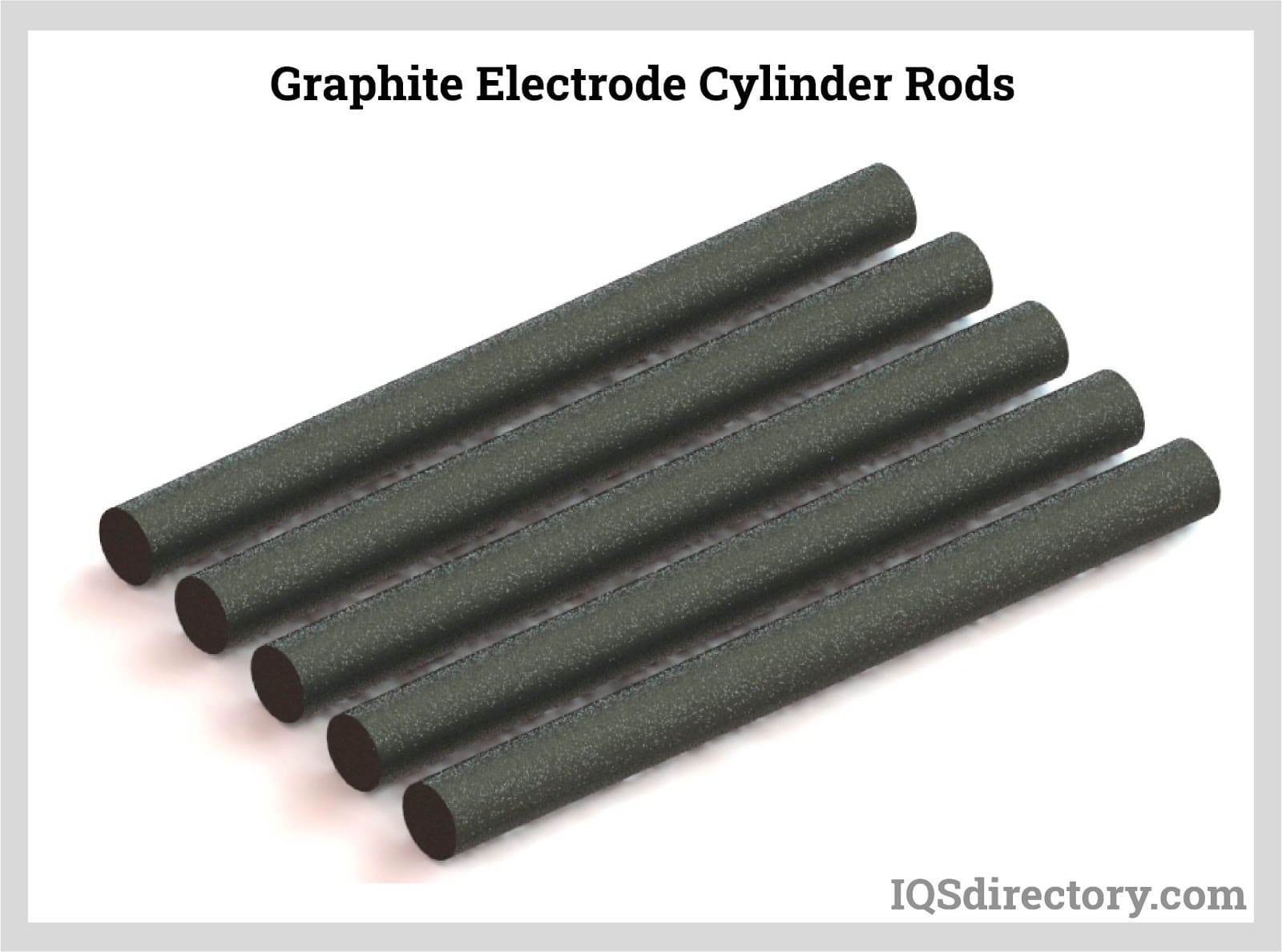

GraphiteStore.com offers graphite machining for graphite products and parts, including graphite rods, graphite fixtures and cathodic protection anodes. We stock certified grades or can obtain economical imported grades. GraphiteStore.com provides machined graphite to a number of diverse industries and markets.

At Graphite Sales, Inc., we have been at the forefront of the graphite machining industry since 1971, delivering unparalleled expertise and precision in every project we undertake. Our legacy is built on a deep understanding of graphite's unique properties and an unwavering commitment to quality. Over the decades, we have honed our skills and expanded our capabilities, ensuring that we meet the...

More Graphite Crucible Companies

Graphite crucibles are the perfect tool for metal casting because of their thermal conductivity, high-temperature resistance, low thermal expansion coefficient for high-temperature applications, and anti-strain characteristics to rapid heating and cooling. They also have great chemical stability and are resistant to acids and alkaline solutions.

Natural graphite, a crystalline form of carbon that occurs in nature, is used to make graphite, which is then combined with carbon dioxide or a lump of clay that resists fire. Petroleum pitch and coke, byproducts of oil refining, are processed to produce synthetic graphite; because of this, it has a lower sulfur concentration and a higher, purer, fixed carbon content.

A graphite crucible offers a non-reactive container that can withstand the high temperatures required for melting and treating metal. Crucibles offer a reliable container that won't react with the metals or other materials burned at high temperatures. Carbon is found in graphite, which can look like flakes or sheets. Graphite can create heat-resistant, long-lasting jars and containers when combined with clay. Graphite crucibles, on the other hand, can be brittle and should be handled carefully, just like many ceramic containers.

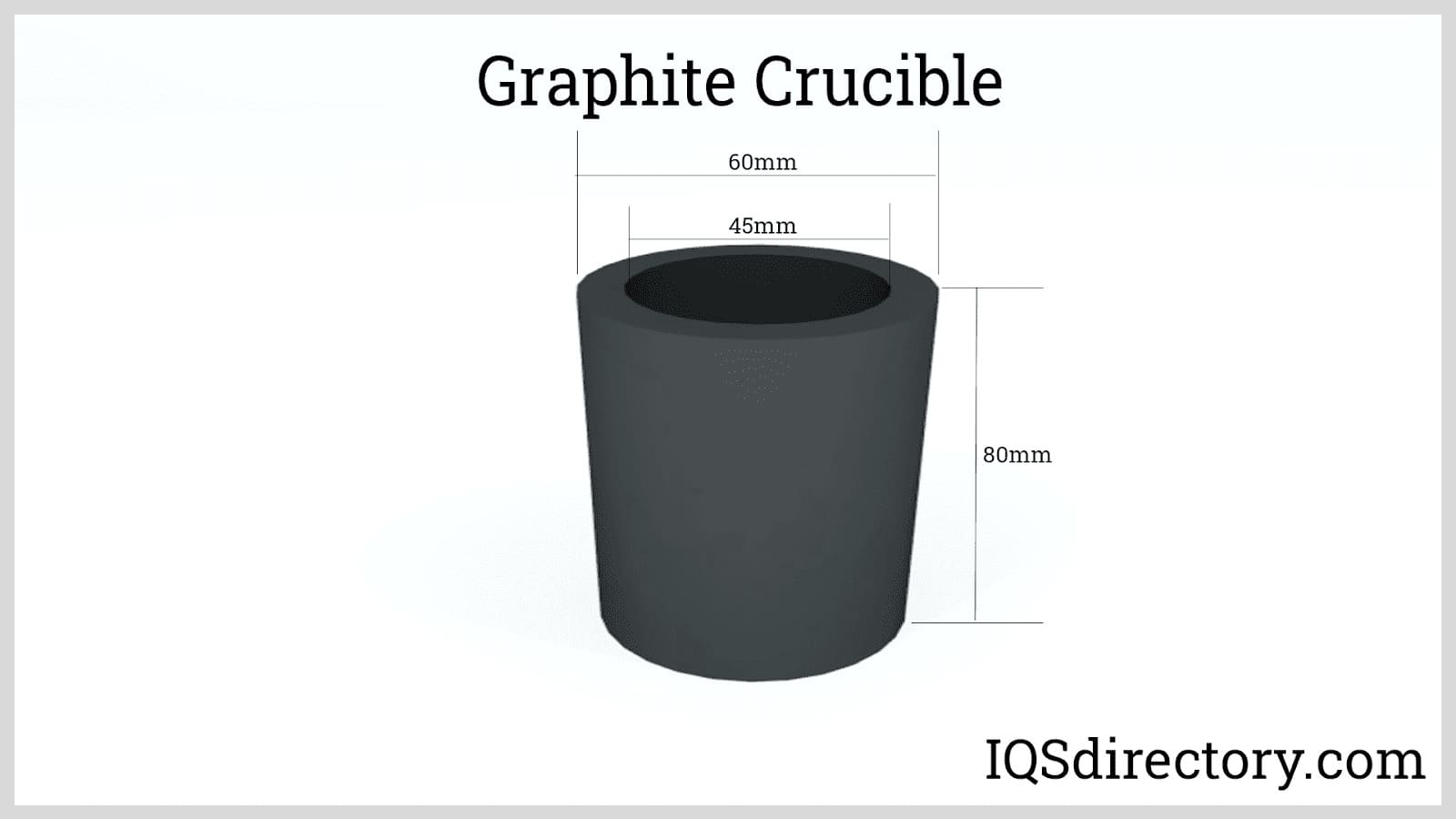

Graphite Crucible Shapes

The main difference between several crucible types is their shape. One shape is called “bilge,” which indicates a barrel shape. In addition, graphite crucible shapes are sorted by letter of the alphabet, so the first crucible shape, or “A” shape, is a cup shape common among crucibles. Since an open cup design is simpler to produce than a barrel shape, "A" shaped crucibles may be less expensive.

Graphite crucibles sorted by letters are further broken down into subgroups based on the shape, interior diameter, outer diameter, and height of the crucible.

The kind of crucible used depends on the kind of metal being treated. The crucible's construction and design must hold the metal at its maximum melting point. The chemical and physical interactions between the metal and the crucible also affect this.

Metals Melted In Graphite Crucibles

Copper

Due to its resistance to thermal shock, a silicon carbide graphite crucible is used to process copper-based alloys that are melted in a fuel-fired furnace.

Aluminum

Carbon or ceramic-bonded clay graphite and silicon carbide are used as crucibles for the production of aluminum and aluminum alloys since these metals melt at 750 °F to 2912 °F (400 °C to 1600 °C).

Gold

Superior-grade graphite crucibles for melting gold have great mechanical strength, are resistant to oxidation and thermal shock and have thermal stability. They are also built to endure more than 3632° F (2000° C).

Silver

Similar to those used to melt gold, graphite crucibles for melting silver may sustain temperatures as high as 3632 °F (2000 °C). Natural graphite serves as the material for the crucible's body, retaining its chemical and physical characteristics. When melting at a higher temperature, the thermal coefficient is less, but it has strain resistance to sudden changes in temperature.

Brass

Graphite crucibles can sustain temperatures above 3632 °F and are identical to those used to melt gold. The crucible's body is made of natural graphite, which retains its chemical and physical characteristics. Although the thermal coefficient is low when melting at a high temperature, it has strain resistance to sudden changes in temperature.

Use of Graphite Crucibles

Graphite crucibles are perfect for the casting process since they are non-reactive. Their superior heat efficiency aids in speedy metal melting for shorter production cycles. In addition, graphite crucibles are strong and long-lasting because they are impervious to chemicals and corrosion and unaffected by the environment in the workshop.

A graphite crucible should be properly stored and conditioned. Before usage, a new graphite crucible needs to be in condition. After two hours at 500 degrees Fahrenheit (260 °C) in the oven, the crucible should be removed and allowed to cool slowly in a dry area. Removing moisture keeps the crucible from splitting. Crucibles should be kept dry and should be reconditioned if they become wet.

Temperatures are raised during casting to lower the tensile and yield strengths of the metal alloys used. Depending on the type of metal, different temperatures are required for melting. The temperature of the crucible and the alloy being cast are two variables that affect casting. Due to its great resistance to the effects of temperature increases, graphite crucibles can supply the right vessel for casting, regardless of the type of metal alloy.

After use, a graphite crucible needs to be thoroughly cleaned. Metal shouldn't be allowed to cool in the crucible. When reheated, residual metal can expand and cause the crucible to break. Instead, use crucible tongs that are compatible with the crucible's design. To avoid cracking, the tongs should hold the crucible without applying pressure to the sides.

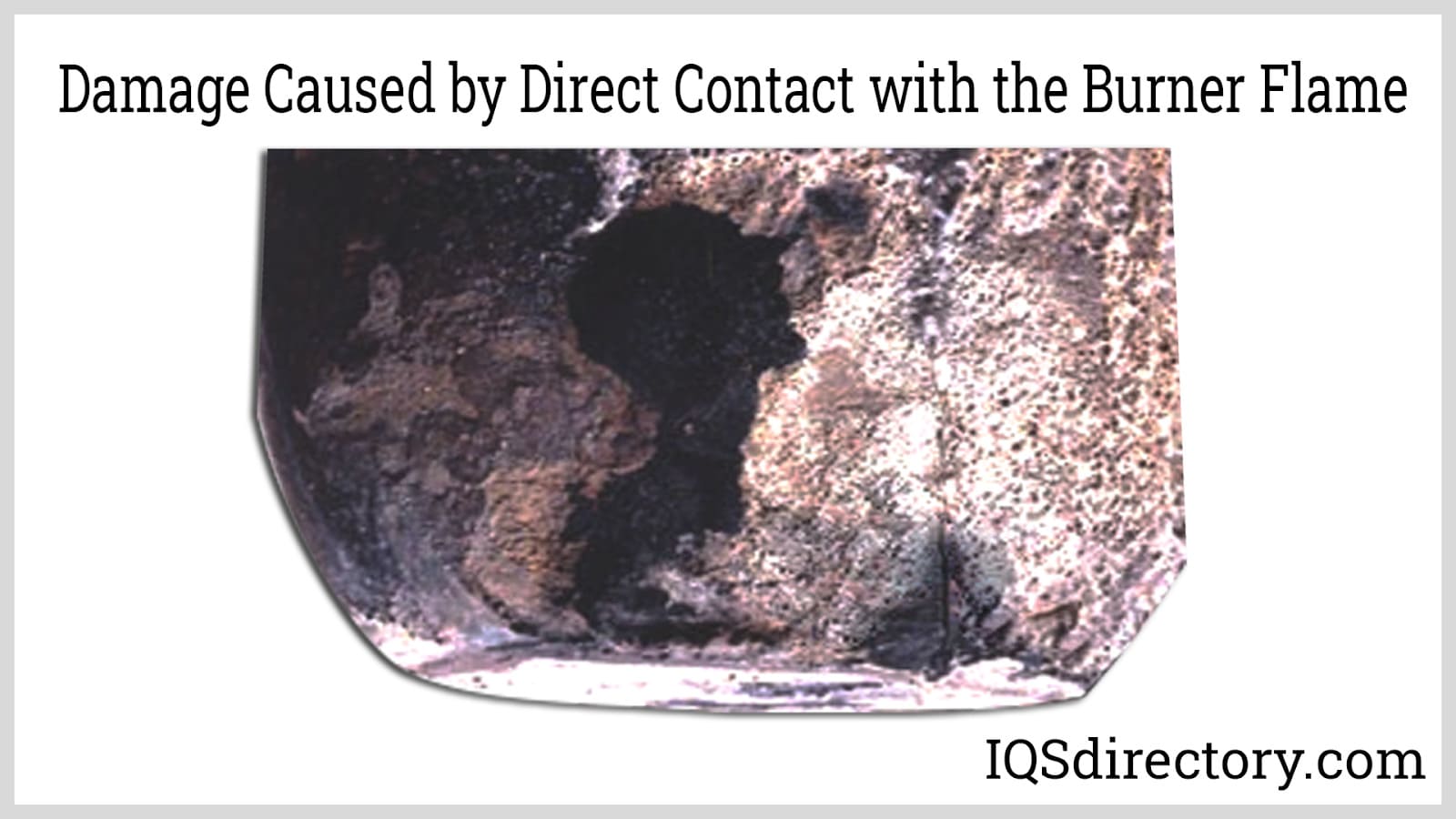

Improper use or handling can cause damage to graphite crucibles. They shouldn't be used with iron-containing metals since the iron will immediately react with the carbon in the crucible, altering or destroying the metal's composition. Before being heated, a crucible should be filled with loosely packed solid metals. A closely packed crucible may fail or crack if the metals expand. Never add water or wet metals to molten metal in a crucible since doing so could result in a steam explosion or cause the crucible to fail.

Choosing the Correct Graphite Crucible Supplier

To ensure you have the most constructive outcome when purchasing graphite crucibles from a graphite crucible supplier, it is important to compare several companies using our directory of graphite crucible suppliers. Each graphite crucible supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each graphite crucible business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services