Contact Technologies

Contact TechnologiesRequest A Quote

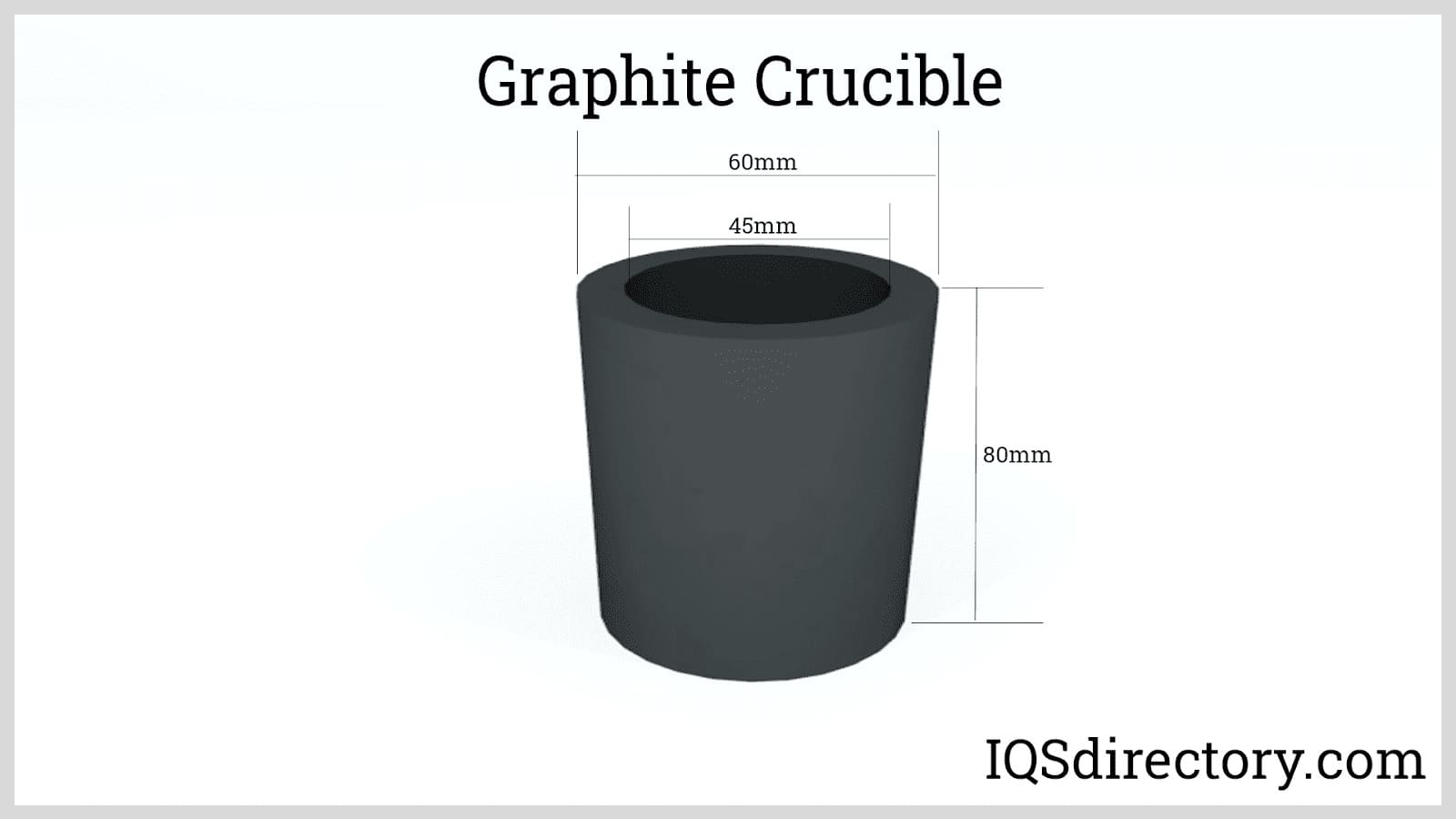

St. Marys, PAContact Technologies is a leading manufacturer of machined graphite products and solutions, providing high-quality products and services to a broad range of industries since 1995. The company is based in St. Marys, Pennsylvania, and operates a state-of-the-art manufacturing facility equipped with the latest CNC machining and manufacturing technologies. Contact Technologies specializes in the production of custom machined graphite products, including graphite heating elements, crucibles, boats, tubes, and other graphite components. The company also offers a variety of standard graphite products, including EDM electrodes, graphite blocks, and rods. The company's team of experienced engineers and technicians use advanced software and CNC machining equipment to produce high-precision graphite parts with complex geometries and shapes. They work closely with their customers to understand their unique needs and requirements, providing custom solutions that meet their exact specifications. Contact Technologies is committed to delivering high-quality products and services to its customers. The company has a strict quality control system in place to ensure that all its products meet the highest standards of quality and performance. They are ISO 9001:2015 certified, which guarantees that they follow strict quality control procedures at every stage of the production process. In addition to its manufacturing capabilities, Contact Technologies offers a range of value-added services to its customers. These services include graphite impregnation, coating, and polishing, as well as assembly and packaging services. The company also maintains an extensive inventory of raw materials, which allows them to respond quickly to urgent orders. Contact Technologies serves a wide range of industries, including aerospace, automotive, electronics, medical, and semiconductor. Their machined graphite products are widely used in applications that require high thermal conductivity, high temperature resistance, and chemical resistance. The company has a strong focus on innovation and invests heavily in research and development to stay at the forefront of the industry. They have a team of experienced engineers who work on developing new products and solutions to meet the evolving needs of their customers. Contact Technologies is committed to sustainability and has implemented environmentally friendly practices in its manufacturing processes. The company uses renewable energy sources, such as solar power, to power its manufacturing facilities. They also have a recycling program that recycles spent graphite electrodes and other graphite products, reducing waste and conserving resources. In summary, Contact Technologies is a trusted provider of high-quality machined graphite products and services. Their commitment to customer service, high-quality manufacturing processes, and range of value-added services make them a reliable partner for any project. Their focus on innovation and sustainability also ensures that they remain a leading player in the machined graphite industry.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

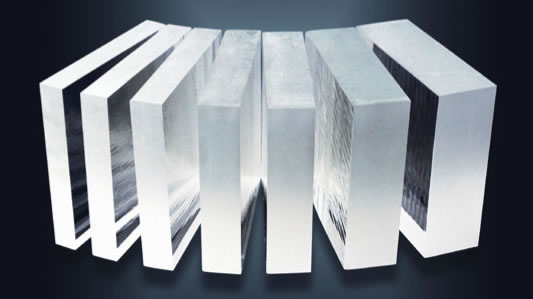

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

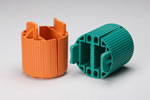

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services